Sustainable supply chains are a hot topic in the business world today. Some 8 out of 10 supply chain organizations have sustainability efforts under way.

As companies face increasing pressure to reduce their environmental impact and support fair labor practices, many are looking for ways to make their supply chains more sustainable.

Remember when the Ever Given disrupted $60 billion in global trade by getting stuck in the Suez Canal? No one is trying to relive it.

In this article, we’ll explore the concept of sustainable supply chains and discuss some of the key trends and challenges in this area. We will also look at some examples of companies that are leading the way in sustainable supply chain management.

Table of contents

- What is supply chain sustainability

- Sustainable supply chain examples

- Three elements of supply chain sustainability

- Benefits of supply chain sustainability

- Challenges of supply chain sustainability

- Supply chain sustainability best practices

- Supply chain sustainability trends

What is supply chain sustainability?

Supply chain sustainability is the practice of minimizing the negative environmental and social impact of a company’s operations throughout its supply chain. One can achieve a sustainable supply chain by reducing waste and emissions, using eco-friendly materials and energy sources, and ensuring fair labor practices.

How sustainable supply chain management works

For a supply chain to be “sustainable,” it has to meet a few criteria.

- The supplies themselves should be sustainable, such as using recyclable materials in packaging.

- Production and delivery should be as low-emission as possible.

- The socioeconomic impact on factory or fulfillment workers promotes fair treatment.

Sustainability is also a logistical issue: without reliable supplies, companies quickly run out of environment-friendly options.

After 2022—a year in which supply chain issues forced companies to turn to expensive high-emissions air freight—businesses are looking for ways to achieve sustainability in every facet.

Sustainable supply chains vs. green, ethical, and responsible supply chains

There are a few different terms used to describe supply chain sustainability. They are often used interchangeably, but have slightly different meanings.

- Green supply chains are focused on reducing the environmental impact of a company’s operations, such as by reducing waste and emissions and using eco-friendly materials and energy sources.

- Ethical supply chains are focused on ensuring fair and humane treatment of workers throughout the supply chain, including by adhering to labor laws and protecting workers’ rights.

- Responsible supply chains are focused on promoting transparency and accountability throughout the supply chain, including by disclosing information about suppliers and their practices and working to prevent corruption and other unethical behavior.

Sustainable supply chains are focused on minimizing the overall environmental and social impact of a company’s supply chain. They include elements of all three supply chain types.

Sustainable supply chain examples

Understanding the trends in sustainable supply chains is only one side of the coin. It also helps to know what specific brands are doing to meet the increasing need to build durable, sustainable supply chains.

L’Oréal

- What it did: L’Oréal adopted a new focus on agility, evolving its supply chain toward the goal of reducing its greenhouse gas contributions by 50%. By the end of 2020, many of its distribution centers already achieved the goal of using 100% reusable plastic.

- Why it works: Acceleration. L’Oréal recently sped up its solidarity sourcing initiatives to diversify its supply chain. The company also incorporated a program of demand, sensing anticipated planning (using data operations to improve demand forecasting) to avoid supply chain challenges caused by inaccurate estimates.

- What benefit it ties to: In addition to the environmental results, L’Oréal’s agile strategy will give it the ability to respond in real time to market expectations. In other words, its supply chain is more sustainable and resilient.

Egglife

- What it did: Egglife, an egg-white-based food wrap brand, brought on Cynthia Waggoner, formerly of Kraft Foods, as a lead supply chain officer.

- Why it works: Egglife uses cage-free egg whites from American Humane Society–standard sources. Though Egglife was founded only in 2019, the company’s rapid growth—recently expanding to 8,000 outlets—required a dedicated supply chain officer who could help sustain growth without sacrificing these standards.

- What benefit it ties to: More and more companies are finding that supply chain hires, or elevating operations positions, are paying dividends in logistics. Egglife anticipated doubling its production capacity in 2022 while remaining committed to cage-free eggs.

Three elements of supply chain sustainability

The three elements of supply chain sustainability are social, environmental, and financial.

- Social emphasizes ensuring workers are treated fairly and humanely, as well as promoting social responsibility and good citizenship in the communities where the company operates. As examples, employers can follow labor laws, protect workers’ rights, provide fair wages and benefits, promote diversity, and help develop communities.

- Environmental involves minimizing a company’s environmental impact, such as reducing waste, cutting emissions, using eco-friendly materials and energy sources, and encouraging conservation. A few examples are reducing greenhouse gas emissions, conserving water, and decreasing or eliminating hazardous materials.

- Financial includes ensuring long-term financial health and stability for companies and their supply chain partners. Practices can include improving operational efficiency, reducing costs, and investing in sustainable technologies.

Companies that focus on sustainability can improve their bottom line, reduce financial risk, and build stronger, more resilient supply chains.

Benefits of supply chain sustainability

A sustainable supply chain represents more than a commitment to environmental and social impact. Supply chain issues in recent years have highlighted how a healthy supply chain can impact business growth.

- Increased revenue. ESG (Environmental, Social, and Governance) initiatives like a sustainable supply chain have a demonstrable impact on business growth. According to McKinsey, “ESG performers enjoy faster growth and higher valuations than other players in their sectors, by a margin of 10 to 20 percent in each case.”

- Higher ESG performance. As more companies look for ways to improve ESG, the supply chain represents the majority of opportunities. More than 90% of the environmental impact of most consumer goods comes from the supply chain.

- Better supply chains also improve global impact. Businesses concerned about forced labor practices or the high-emission extraction/processing of fossil fuels can mitigate these problems by looking to the supply chain first.

- Meet stakeholder demands. Investors are increasingly looking for companies with strong sustainability practices, and are willing to invest in or divest from companies based on their approach to sustainability. Companies that prioritize sustainability in their supply chain management can potentially attract more investment, pass compliance audits, and improve their financial performance.

- Cost savings. Lowering emissions and waste can lower your energy and resource usage. Green technology also improves efficiency, which can reduce long-term costs. Plus, working with suppliers that use sustainable practices attracts more customers and leads to more revenue.

Challenges of supply chain sustainability

Today’s brands face sustainability challenges when supply chains break down. Some of those reasons were typically as follows:

- Turning to expensive air freight to supplement supply chain holes

- Shipping delays in a high-expectation consumer environment

- Over-reliance on single suppliers

Turning to expensive (and high-carbon) air freight

When a single bottleneck shows up in an established supply chain, companies turn to the easy, convenient solution: flying over it.

The problem with air freight is it’s expensive; it creates high emissions per pound delivered. CO2 emissions from air freight are a small fraction of the overall carbon puzzle, but air freight has outsized impacts on pollution. Despite constituting only 2.5% of total carbon output, commercial aviation makes up 3.5% of warming effects.

Even worse, the carbon footprint of air freight tends to be no better than packing your supplies into a car and simply driving it to the destination.

For comparison, even an oil tanker only contributes about 1% of the carbon footprint air freight does when weighed in grams per cargo mile.

And the trend isn’t going anywhere. By 2050, the Environmental and Energy Study Institute anticipates air travel will have tripled in its carbon footprint. It’s not only carbon-expensive, either.

Shipping delays meeting high expectations

Businesses don’t turn to expensive, higher-carbon air freight without good reason. In 2021, that reason was that global supply chains couldn’t keep up with demand.

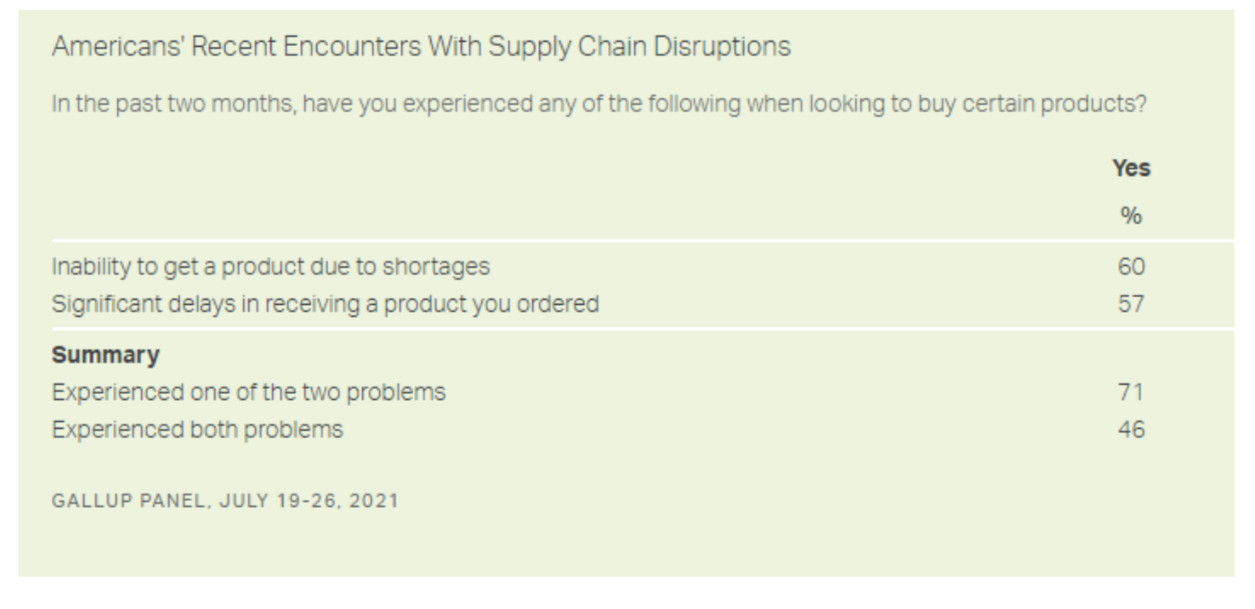

According to a Gallup poll, 60% of customers couldn’t purchase an item in the summer of 2021. Not far behind, 57% of customers reported noticeable delays in receiving shipments.

If air freight is the symptom, shipping delays are the underlying cause.

Over-reliance on single suppliers

The supply chain disruptions of in recent years showed how reliant the world has become on a steady stream of cheaply shipped goods.

When a company can rely on a single manufacturer with a steady, secure supply chain, the arrangement locks in inventory and creates a predictable carbon footprint.

But when there’s a logjam at the Port of Los Angeles, preventing inventory from arriving via large container vessels ( three grams of carbon per tonne-km of cargo), it forces companies to use alternative methods of delivery.

Delivery by truck tends to be 26 times less carbon-efficient than large container vessels. Delivery by air? 145 times less.

With multiple sources of inventory, a company at least has the choice to select the most sustainable option for deliveries.

Supply chain sustainability best practices

How are today’s businesses adapting when it comes to building a sustainable supply chain that doesn’t fall to the whims of unpredictable demand trends?

1. Set sustainability goals

Despite having a long-term sustainability vision, many organizations lack ROI-backed initiatives. According to a 2022 study of 525 supply chain leaders, improving visibility is the number one priority for the upcoming year.

Yet, some 33% of companies reportedly lack a business case for supply chain visibility, and almost half of respondents said their companies struggle to measure the return on supply chain activities.

Digital tools like FourKites can help you capture metrics, set key performance indicators (KPIs), and establish governance.

Some top metrics organization measure are:

- Greenhouse gas emissions

- Waste reduction

- Water usage

- Energy consumption

- Use of renewable energy sources

- Labor practices

- Supply chain transparency

- Management of hazardous materials

- Biodiversity conservation

- Resource efficiency and conservation

Setting goals can help create a holistic, end-to-end view of the supply chain, allowing you to track materials, working conditions, and more to measure program effectiveness and visibility.

2. Set flexible contracts

Making fewer static commitments (such as fixed, long-term contracts with suppliers) helps companies shift to changing trends. “Flexible contract manufacturing enables companies to replace more of their traditional fixed cost base with variable costs to adapt to changing demand,” says Jeff Langely of KPMG Australia.

3. Diversify supply chain sources

In 2021, a McKinsey report found that two-thirds of an organization’s ESG commitments come through its suppliers. By carefully choosing diverse suppliers, businesses can have the greatest impact on sustainable practices. This is especially important in an environment with unpredictable supply shocks.

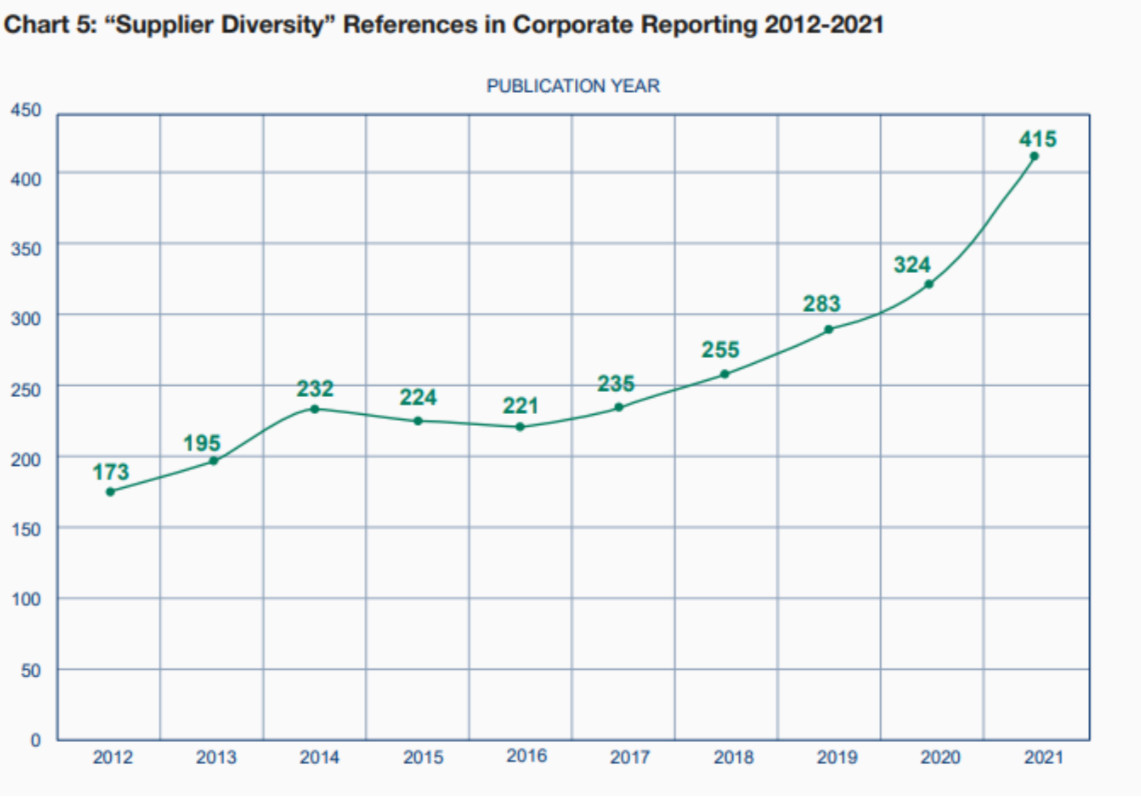

The latter may be the biggest trend emerging. In 2021, corporate reporting references to supplier diversity saw a major upswing:

To build sustainable supply chains, more and more companies are going to the supply chain’s starting point. This helps promote industry in developing economies, where sustainable practices may still need financial support for growth. It also helps each company grow less dependent on single sources, making commerce more resilient to geopolitical supply shocks.

4. Find suppliers that meet your supply chain Code of Conduct

We asked Jackie Rideout, a manager of supplier diversity and sustainability with over 10 years of experience, how she would advise businesses looking for more sustainable supply chains in 2023.

She recommends never relaxing your standards, even as you diversify your suppliers. Every company, Rideout says, should reinforce its commitment to sustainability. Diversify only with suppliers who can meet the criteria you establish. Rideout recommends using an RFI (request for information) to start these new supplier relationships.

5. Focus on transportation

Rideout calls transportation the largest impact on a company’s sustainability. Efficient routes reduce travel and therefore emissions. To accomplish this, Rideout recommends limiting LCLs (less-than-container loads) and maximizing container utilization. Other business practices, like updated refrigeration equipment in warehouses and reusable packaging, also have lasting effects.

6. Optimize your network

Map out your supply chain from beginning to end, identifying key locations for warehousing and distribution centers based on your customer locations, Rideout recommends.

Maggie M. Barnett, COO of ShipHero, agrees, noting how ShipHero has optimized its network to increase sustainability. She calls last mile one of the points of “biggest impact” in the supply chain.

Domestically, merchants have the opportunity to deploy a distributed warehouse network model, where the product is strategically placed in zones where demand is highest. This allows merchants to continue to meet rapid shipping speeds, while keeping product transportation on the ground to decrease reliance on airplanes for fast delivery.

—Maggie M. Barnett

Supply chain sustainability trends

1. Elevate supply chain leadership within your business

US digital grocery sales grew another 20% throughout 2022. This helped feed the growth of companies like Egglife, as well as Supernatural, a direct-to-consumer baking brand.

Supernatural started with a head of operations working on a contract basis in 2021. Egglife hired a former Kraft executive as its top supply chain officer. Placing greater emphasis on building sustainable, scalable supply chains has kept both companies growing without overwhelming current leadership.

Elevating supply chain leadership has another benefit: connecting to and building relationships with suppliers. “Brand and supplier relationships need more than just financial benefit,” says Adii Pienaar, founder of Cogsy, an operations-focused software. “It also needs flexibility, predictability and longevity to create a true partnership that ensures that brands always have enough product to sell to their customers.”

For example, Jordi Beneyto-Ferre, Senior Manager of Global Materials and Sustainability at apparel brand Icebreaker, calls 100% traceability and transparency between companies and suppliers the “key to sustainable price chains.”

Through Beneyto-Ferre’s leadership and a commitment to sustainability, Icebreaker is able to enforce strict partner requirements to its fabric mills, suppliers, and distribution center partners. Everything from wastewater compliance to avoiding restricted substances goes through the supplier-seller relationship. These partners also share data, creating better forecasts for shifts in supply and demand.

Rather than just collecting large swaths of data, businesses that actually connect that data to gain a holistic view of front- and back-end information will see significantly more ability to pivot and align with vendors who run sustainably.

Jenn Vande Zande, Editor in Chief, FCEE at SAP

2. Diversify supply sources to help promote ethical worker treatment

L’Oréal’s commitment to solidarity sourcing highlights an advantage of diversifying supplies: it pays real dividends in ESG efforts. L’Oréal began new purchasing strategies in 2020, exposing its supply chain to more remote, underprivileged areas in China.

The project, dubbed Plants like No Other, united several brands: L’Oréal, Yves St. Laurent, and Lancôme. Together, these brands used their buying power to promote employment opportunities for working women in China. L’Oréal reports the project helped 913 people (two-thirds of whom are women) work full time.

In doing so, these beauty brands added a new leg to its supply chain while also doing good.

3. Reduce single-use packaging whenever able

In 2021, the ecommerce industry used an estimated 2.6 billion pounds of plastic—a number expected to almost double by 2025.

Recent estimates suggest that trend is not slowing. According to Gartner, even commitments like those of Apple aren’t having a big impact on the overall trend.

The key problem: single-use plastics. Companies will have to adapt to future regulations, such as a UK law requiring a tax on plastic packaging that came into effect in 2022.

According to S&P’s Sustainability Yearbook 2022, an assessment of several thousand companies, finding sustainable packaging alternatives continues to be a major industry trend driving product development and innovation.

The yearbook recommends focusing on the following packaging materials:

- Recycled

- Certified and renewable raw materials

- Reusable packaging

4. Reliance on carbon credits

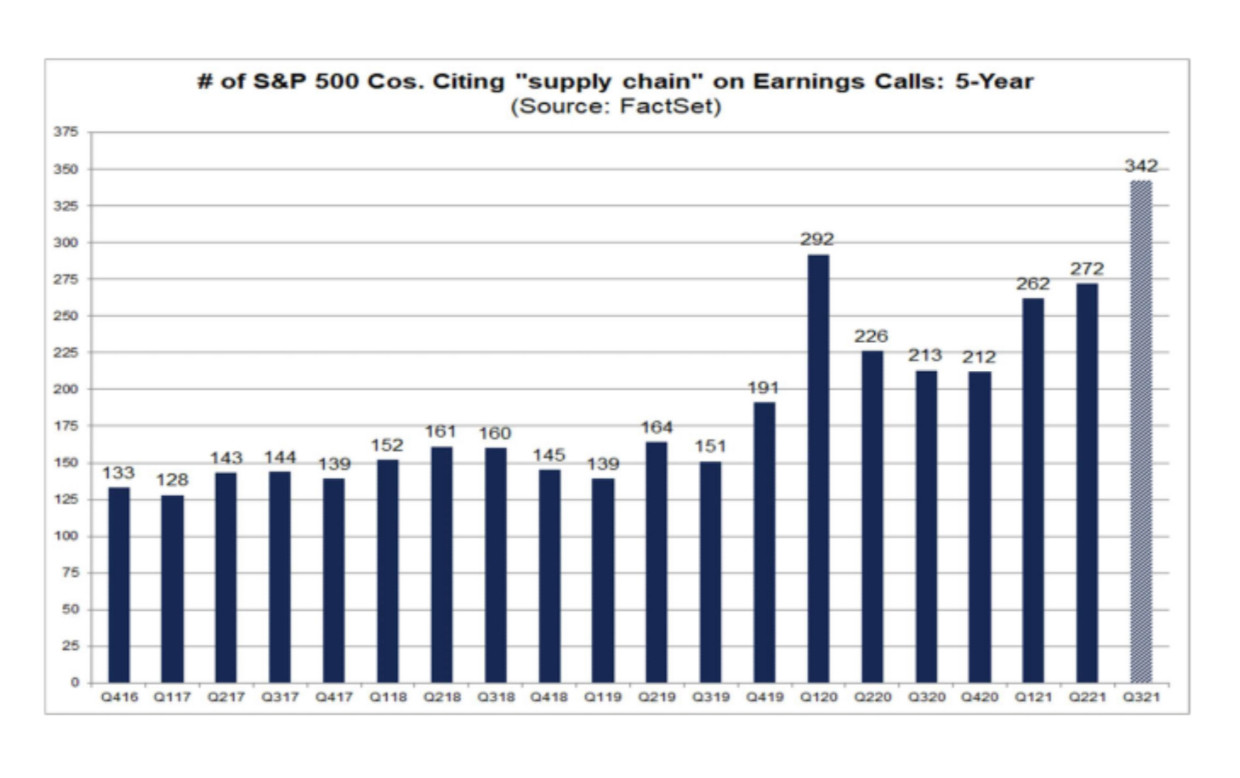

The geopolitical upheaval at the start of 2022 has highlighted the need for stable, sustainable supply chains—so much so that the overarching trend has become the story of supply chains themselves. The phrase “supply chain” has never been so prevalent in the earnings calls of major companies.

There’s a reason for this: supply chain challenges have never taken such a bite out of business earnings. This is likely due to sustained demand in the face of geopolitical uncertainty, first from COVID-19 and now from Russia’s invasion of Ukraine.

The damage to the bottom line highlights the need for sustainable supply chains. Gap, for example, turned to air freight to fill in the gaps in its supply chain. This swung the company from a $234 million profit in one quarter to a $16 million loss in its most recent quarter.

Another option for increased sustainability, carbon credits, can be just as expensive. Supply chain challenges helped contribute to an explosion in carbon credit costs in 2021. In some cases, carbon credit prices catapulted nearly 1,000%.

One pitfall is relying too much on carbon credits to offset emissions. Challenges to these credits have come to light recently. If you do go this route, be sure that you can stand behind how they work. Share it openly with your customers on an FAQ page. The less ambiguous climate initiatives are, the fewer customers will challenge them.

—Frazer Kinsley, Director of Consulting Services at 3PL Central and Managing Partner of Kinsley Partners

5. Partnerships with sustainable logistics providers

Another trend cropping up is partnering with sustainable logistics providers. For example, fashion brand Rebecca Minkoff recently partnered with package tracker Route to offset carbon emissions, reports Glossy.

Ecommerce platforms like Olive are also attracting fashion brands looking to kick off sustainable initiatives. Using Olive, companies like menswear brand Rhone can let customers return unwanted items, which are then sold by Olive’s consignment services. Customers earn up to 80% of the sale, and Olive gets the rest.

Creating more sustainable supply chains

Building a sustainable supply chain is not a single initiative. To meet the needs of an evolving and complex world, a supply chain needs to be responsive to shifting demands in packaging and carbon emissions.

Sustainable supply chains are built at the organizational level. Companies succeed with ongoing optimization efforts aimed at improving sustainability programs and corporate social responsibility. Even better, they can set sustainability performance-based targets to track their progress.

Today’s top brands are making commitments to better-sourced materials. They’re elevating supply chain executives to positions of higher leadership. Ultimately, they are making a sustainable supply chain a priority.

If companies are going to live up to their ESG commitments, it has to be.

Sustainable supply chain FAQ

What is a sustainable supply chain?

A sustainable supply chain is one that considers the environmental and social impacts of your products, from procurement and manufacturing to the end of the product life cycle.

What are examples of supply chain sustainability?

Examples of supply chain sustainability include reducing waste and emissions, supporting human rights and fair labor practices, using sustainable materials, and investing in green technology.

What are the three elements of supply chain sustainability?

- Environmental

- Social

- Economic

How can supply chains become sustainable?

Supply chains can become more sustainable by implementing practices that reduce their environmental impact and support fair labor practices. This can involve things like using environmentally friendly materials and transportation methods, working with suppliers who use sustainable supply chain practices, and investing in green technology.