It’s that time of year again! As the weather starts to change and the holidays approach, retailers across the country are preparing for the rush of seasonal shopping.

But along with the excitement of the season comes a unique set of challenges, from managing inventory to dealing with customer demands.

In this article, we’ll look at the biggest challenges retailers face managing seasonal inventory, and the best tips from retail experts for overcoming them.

What is seasonal inventory?

Seasonal inventory is the stock that businesses acquire to meet increased demand during specific times of the year, such as holidays or seasonal events. This type of inventory helps companies manage fluctuations in sales and ensure product availability during peak seasons.

Seasonal inventory challenges

Some of the challenges presented by seasonal inventory include: dead stock, stockouts, and storage issues.

Dead stock

Dead stock is one of the biggest challenges with seasonal inventory. The term dead stock refers to inventory that you can’t sell. It’s a big loss of revenue for retailers.

It’s especially bad with seasonal inventory. Retailers stockpile products in anticipation of future demand. If they don’t meet demand, they are stuck with excess merchandise that is sometimes unsellable.

For example, a retailer might have a lot of Halloween-themed merchandise left over after October 31. How are they going to get rid of all that stuff?

Dead stock can be dealt with in a few ways; none are ideal.

- Retailers can try to sell the items at a discount, but that usually doesn’t make up for the loss in revenue.

- They can donate the items to charity, but that doesn’t always make sense logistically. Somebody has to deliver it, or somebody has to pick it up.

- They can just throw the items away, which, for a business, is not a sustainable solution.

Managing seasonal inventory, then, requires accurate demand forecasting, since large amounts of inventory can become obsolete. Also, holding costs can build up if inventory is not sold as anticipated.

Stockouts

The opposite situation, stockouts, is also a problem. Stockouts occur when a product is no longer available for purchase because it has sold out. They cost North American retailers more than $300 billion each year.

Companies using seasonal inventory build up stock during periods of low demand and store it for periods of high demand. If future demand exceeds the amount of product stockpiled, you can easily run out of stock.

Storage issues

Another area in which seasonal inventory can be a challenge for retailers is storage. Seasonal items take up valuable space in warehouses and stores, and if not managed properly, can lead to cost and handling problems.

The big question for most retailers is how much inventory to store. They must compare the costs of storing additional seasonal inventory against the cost of satisfying fluctuations in demand.

Examples of seasonal inventory

For most businesses, inventory demand fluctuates with the seasons; it can be anything from clothing to home goods and beyond. Here are some common types of seasonal inventory:

Holiday inventory

Your first thought about seasonal inventory was likely holiday products. Christmas, Halloween, and Labor Day weekend are all examples of holiday inventory. They all have specific items that consumers buy only during the holiday season.

For example, the Christmas season usually includes a lot of lights, decorations, prepared foods, paper plates, and cutlery. To increase sales, you can run promotions to target customers leading up to Christmas.

Summer or winter apparel

For apparel merchants, clothing for summer or winter is a basic example of seasonal inventory.

Depending on where you operate, summer may be your busiest season, due to warmer weather and vacations. In the summer, people tend to buy more swimsuits, shorts, and tank tops. Cold winter weather may cause sales to drop, but people will still need to buy coats, hats, and gloves.

Event inventory

Event inventory relates to specific events such as the Super Bowl or the Fourth of July. It can include things such as kitchen supplies, decorations, clothing items like hats and t-shirts pint glasses, and flags.

Seasonal inventory management methods

- Just-in-time inventory (JIT)

- FIFO

- LIFO

- ABC analysis

- Economic order quantity (EOQ)

Let’s look at some of the various inventory management methods available for handling seasonal inventory.

Just-in-time inventory (JIT)

Just-in-time inventory (JIT) is a system where you only receive inventory as needed in small quantities. It’s a way to reduce holding costs and dead stock.

There are some downsides to using JIT for seasonal inventory. It’s ideal for businesses with stable demand and predictable supply chains, but if you order from a supplier and they don’t have inventory available, or have long lead times, you’ll go out of stock. That’s why retailers normally order seasonal inventory ahead of time.

However, JIT is good for retailers with a good forecasting system in place. If you can predict demand accurately, you can reduce costs and improve efficiency with JIT.

Learn more: Save Time and Money with Just-In-Time Inventory: A Guide for Retailers

FIFO

First in, first out (FIFO) is a popular inventory valuation method. Using FIFO, the first items you receive are the first to be sold. FIFO provides accurate inventory levels because it considers everything you carry in stock, not just recently received items.

FIFO is ideal for retailers selling perishable products or seasonal products like clothing. However, it can be difficult to implement if you have multiple SKUs or products with different shelf lives.

Learn more: 4 Inventory Valuation Methods for Retailers (+ How to Choose One)

LIFO

Last in, first out (LIFO) assumes the stock you acquired last is sold first.

If you pay a premium for stock from a supplier due to seasonal demand, LIFO helps recover the higher cost by moving that inventory first. LIFO is ideal if you sell non-perishable products, because older stock can remain in your warehouse for longer.

ABC analysis

The ABC analysis model prioritizes products based on their value by categorizing inventory into three buckets: A, B, and C.

- A: high-value products that generate the most profits.

- B: mid-tier products that have average sales velocity.

- C: products that sell quickly but don’t generate much profit.

Running an ABC analysis can help you save money by prioritizing inventory purchases and selling off obsolete inventory before it becomes worthless. It can also help you keep track of your most important assets and prevent them from becoming obsolete during the season.

Learn more: How to Run an ABC Analysis: Find Your Top (and Worst) Performing Inventory

Economic order quantity (EOQ)

EOQ helps you identify the optimal quantity of inventory to order. It takes into account three factors:

- Demand

- Ordering cost

- Holding cost

It’s one of the hardest models to use for the average retailer. It’s recommended that you use EOQ only if you have an experienced inventory manager who has used JIT and EOQ before. Done well, using EOQ can reduce your holding expenses.

Learn more: What Is Economic Order Quantity and How Can I Calculate It?

Types of seasonal inventory demand

There are four main influences on seasonal inventory demand: weather, culture and holidays, migration and travel, and available income. Let’s explore each one:

Weather

When you think of the seasons, you think of weather, and weather plays a clear role in seasonal inventory demand. In some climates, there is never any need for snow gear because it never snows and there is always a need for beach towels. In climates with more distinct seasons, the time of year and the weather will always determine what customers feel the need to buy and, therefore, the products you can successfully promote.

Culture and holidays

Culture and significant holidays have a great effect on seasonal inventory demand, so it’s a good idea to be ready. Whether it’s Christmas, Thanksgiving, or July Fourth, some products are definitely more popular at certain cultural times of the year.

Migration and travel

Summer vacations are the obvious time to look out for when thinking about preparation for migration and travel, but with cheaper rates and smaller crowds, many Americans like winter vacations just as much. So stock up on hats, gloves, and scarves when the time is right.

Available income

Of course, many factors affect available income, and shopping budgets can be hard to predict from person to person or family to family. Having said that, certain times of year might yield a boost in finances, like the close of the tax season, when people get their returns. This could help to boost sales of certain luxury items, for example.

Tips to improve seasonal inventory management

With seasonal inventory, your sales period is limited, and once the season is over, leftovers can be difficult to move.

Let’s look at a few ways to improve seasonal inventory management, so you can meet demand and make more sales.

- Leverage historical data for forecasting

- Run a presale

- Bundle complementary products

- Discount slow-moving inventory

- Consider international marketing

- Closely monitor inventory metrics

- Streamline fulfillment

1. Leverage historical data for forecasting

One of the best ways to improve forecasting is by looking at past sales patterns. That way, you can better understand what customers are likely to buy and when they’ll buy it. You can use this information to adjust inventory levels accordingly.

Retailers use inventory management software to collect and analyze data for forecasting. Javad Nasiry, a professor at McGill University’s Desautels Faculty of Management, suggests, “The more you know about your demand, the less uncertain you are about demand. That means you can manage your inventory better and reduce inventory levels in your warehouses, because keeping inventory is costly.” It should also be done at the category and product level.

Two methods you can use to plan seasonal demand include:

- Sales forecasting. Use historical revenue numbers to predict future sales. For example, if you compare summer sales over the past three years, you may find that they average 25% more sales volume than you had at the beginning of the year. It’s safe to assume that it’ll happen again this year.

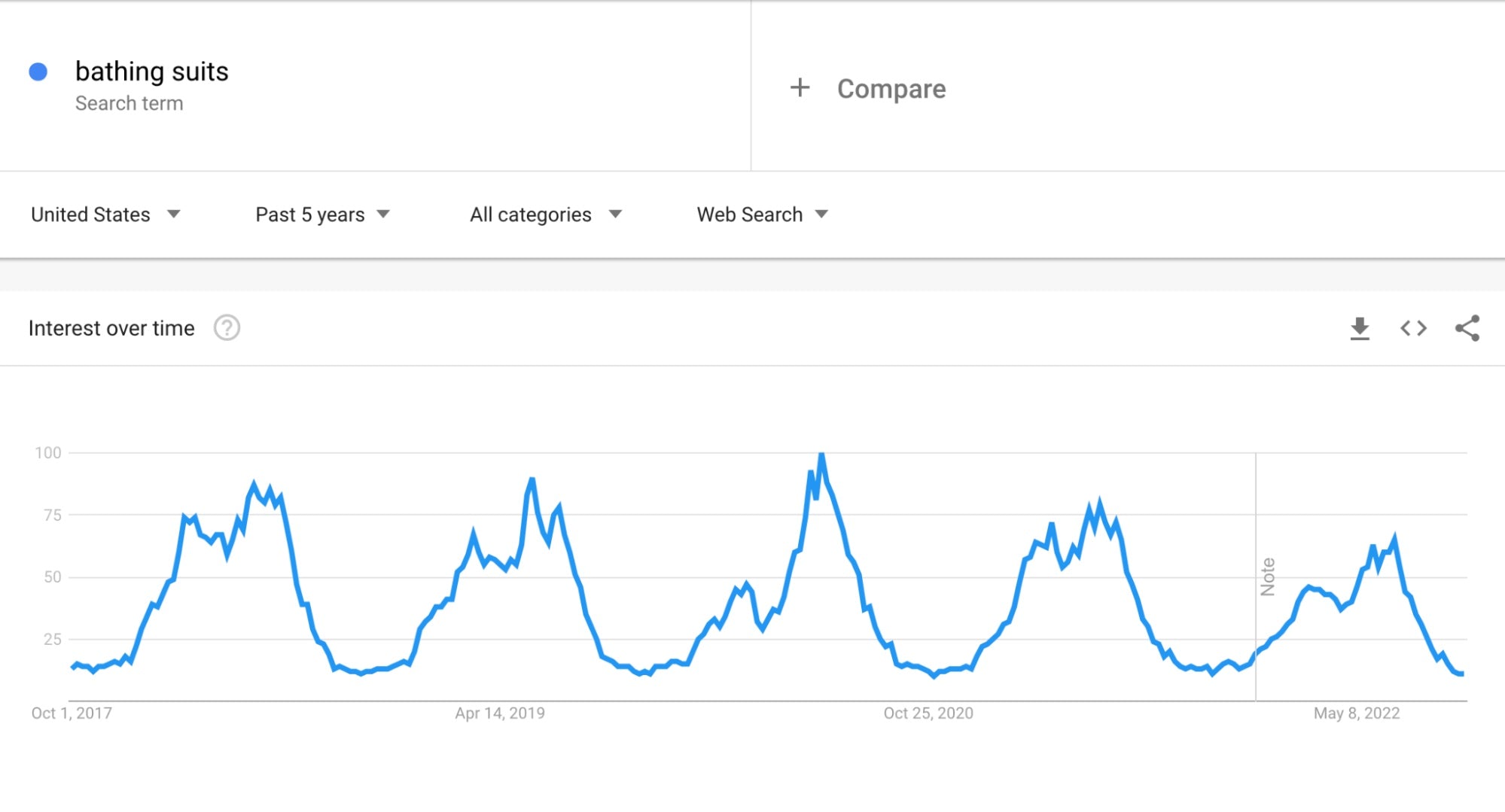

- Seasonal trends. Some products are more popular than others throughout the year. Predict seasonal shifts by using Google Trends to show fluctuations in interest. You can see in the graph below that searches for “bathing suits” peak around May–June, when people are gearing up for the summer.

By forecasting seasonal demand, you’ll understand exactly how much product to have in stock during those months. Using data from your inventory management system, you can improve your chances of accurately forecasting demand, avoiding overstocking, and reducing stockouts.

Ann McFerran, the CEO of Glamnetic, says, “Demand planning goes further by considering other factors that could impact demand, such as seasonality, consumer taste trends, and even events like a global pandemic. This information is essential for meeting your customer demand while minimizing excess inventory.”

Learn: What is Safety Stock and How Much Do I Need For My Store?

💡 PRO TIP: Shopify POS comes with tools to help you control and manage your inventory across multiple store locations, your online store, and your warehouse. Forecast demand, set low-stock alerts, create purchase orders, know which items are selling or sitting on shelves, count inventory, and more.

2. Run a presale

One way to evaluate the sales potential of seasonal items is by running presales. It’s a tactic that Meredith Dew, owner of clothing brand Wild Melon, uses to gauge seasonal trends.

“I find the biggest challenge with seasonal inventory is ensuring you have enough for everyone who wants it, but not getting stuck with anything after the holiday is over,” she explains. “Once the merchandise is out of season it can be difficult to move without steep discounts.

“One way I manage seasonal inventory is by offering presales. It allows me to have cash flow before investing in the inventory and shows me what the customers are most eager to purchase. Then, I tailor my seasonal stock inventory to match what was bought in the presale.”

3. Bundle complementary products

Bundling complementary products is an effective way to improve seasonal inventory management. According to a Harvard Business School study, product bundling can be an effective tool for increasing sales.

The study found that when gaming brand Nintendo bundled two products together, it sold over 100,000 units and produced more than one million dollars in video game sales.

Ideally, you want to close your season with bundled sales. These promotions can move inventory efficiently, reducing storage costs and unsellable products.

Christmas decorations are a great example of this. Items like wrapping paper and ornaments are useless after December 26, but when heavily discounted as a bundle, people are likely to stock up for next year’s holiday needs.

💡 PRO TIP: Try using apps to upsell and cross-sell more effectively. Apps like Marsello and Frequently Bought Together integrate with Shopify POS and recommend products to store staff based on what they’ve added to a customer’s cart, making it easier than ever to suggest relevant products, and increase basket sizes and order value.

4. Discount slow-moving inventory

Inventory that moves slowly drains a company’s resources. Besides tying up working capital, it takes up valuable storage space and can lead to stockouts.

If inventory is slow-moving, discounting can help, but it must be used judiciously. Done incorrectly, discounting can erode margins and damage your brand.

Brian Lim, CEO and founder of iHeartRaves, says, “One way to improve seasonal inventory management is to offer discounts or promotions on slower-selling items to clear out excess inventory before it becomes obsolete.”

💡 PRO TIP: With Shopify POS, you can create dollar or percentage discounts that get automatically applied to individual items or entire carts at checkout. Once you set up an automatic discount, it works for both online and in-store purchases.

5. Consider international markets

Another way to manage seasonal inventory is by selling products internationally. The seasons in the Northern Hemisphere are opposite those in the Southern Hemisphere. In Australia, winter begins in June, while US consumers are airing out their beach chairs and stocking up on bathing suits.

Retailers can take advantage of these seasonality patterns. Say you’re a sports supplier in the US clearing out skis and snowboards around April. Rather than discount everything and lose out on profit, you can start promoting those products to customers in Australia, New Zealand, or Argentina.

When selling internationally, you need to consider shipping costs, customs regulations, and language barriers. However, if you research and plan ahead, you can successfully sell in world markets.

6. Closely monitor inventory metrics

Staying on top of inventory levels is critical for managing seasonal inventory. This includes:

- Inventory turnover. Shows how fast you restock products compared to how fast they sell. Low inventory turnover means you have too much stock, which means low sales.

- Days to sell Inventory (DSI). Measures the average number of days it takes to sell off inventory. A high DSI suggests that either you’re not managing inventory properly or that your inventory is hard to sell.

- Average inventory levels. Estimates the number of units available in stock over a specific period. You want your average inventory levels to line up with average seasonal sales.

- Total stockouts. Several stockouts during a season indicate poor forecasting and an increased ordering requirement.

Steven Pogson, founder of ecommerce growth agency FirstPier, recommends carefully monitoring your inventory levels throughout the year to plan for seasonal demand. “You want to maintain just enough inventory to satisfy demand, but not so much that you’ll have a ton of leftovers at the end of the season.”

He adds, “Don’t be concerned about low inventory levels, especially if you can swiftly restock your products. Watch for any unexpected drops in your daily sales and inventory levels. The fact that these are items your devoted clients have learned to expect from you will also assist you in identifying your profitable regulars that you must continue selling alongside your seasonal products.”

Pogson recommends that retailers invest in automation to manage seasonal demand. “It’s easy to see your stock levels every day thanks to a reliable POS system. It automatically records every sale and updates inventory data in real time.”

💡 PRO TIP: Only Shopify POS unifies your online and retail store data into one back office—customer data, inventory, sales, and more. View easy-to-understand reports to spot trends faster, capitalize on opportunities, and jumpstart your brand’s growth.

7. Streamline fulfillment

Fulfillment refers to assembling and shipping a customer’s order. Retailers make fulfillment a priority because it impacts customer satisfaction and profits overall. If you can’t fulfill orders effectively, you’ll struggle to sell any products.

A few innovative ways retailers can streamline fulfillment include:

- BOPIS (buy online, pickup in-store). Fifty percent of online shoppers use BOPIS. It’s a popular option for many folks, especially during the holiday season. Buying online and picking up in-store saves people time and money versus ordering by mail.

- In-store pickup. A good option for businesses that have multiple locations. Customers can order items online and then pick them up at a curbside location that is convenient for them.

- Local delivery. A good method for businesses located in rural areas or with products that are difficult to ship. Customers can order items online and then have them delivered to their doorstep by a member of your team.

- Automation. Some tasks are easy to repeat and an automatic process can make them much quicker and more efficient. An app like Shopify Flow empowers you to create custom automations. You can create unique workflows and connect apps together to complete more jobs.

Dustin Kroft, the principal and lead designer at Kroft, says, “Our retail store removes a lot of design restrictions around larger items. With in-store pickup, we can design and sell a series of products that don’t need to ship to California, which helps us be more economical with our order fulfillment for bigger, higher-price-point items.”

📌 GET STARTED: Shopify Fulfillment Network, Shopify’s very own 3PL, was built with merchants in mind. We offer two-day shipping on most orders across the United States, simple pricing, returns support, full integration with your Shopify store, and so much more.

Manage your seasonal inventory more effectively

Seasonal inventory can be tricky to manage. If you order too much inventory ahead of time, you’re stuck with unsellable products year-round. If you don’t order enough product, you’ll have stockouts and disappointed customers.

By following the tips above, you can create a system for your store that helps you meet customer demand and earn more sales throughout peak seasons.

Additional research and content from Alexis Damen.

Seasonal inventory FAQ

What is an example of seasonal inventory?

How do you deal with seasonal inventory?

- Have a plan in place to manage seasonal inventory: Before the season begins, create a plan outlining how you will manage seasonal inventory. This plan should include how much inventory you need to purchase, how you will store the inventory, and how you will manage overstock.

- Take advantage of off-season sales: Many stores offer discounted prices for seasonal items during the off-season. Taking advantage of these sales can help you save money and reduce the amount of inventory you need to purchase during the busy season.

- Monitor inventory levels: Make sure you are regularly monitoring your inventory levels to ensure you have enough stock on hand to meet customer demand.

- Utilize predictive analytics: Utilize predictive analytics to help you anticipate customer demand and make sure you have the right amount of inventory on hand.

- Consider dropshipping: Consider utilizing a dropshipping service to help manage seasonal inventory. This can help you save money and reduce the amount of inventory you need to purchase and store.