3PL inventory management helps retailers reduce costs and improve supply chain efficiency. When implemented correctly, 3PLs handle complex logistics so your business can replenish and ship inventory more efficiently.

But sometimes retailers face challenges when outsourcing to a 3PL. Perhaps you can’t see your partner's stock levels. Maybe you’re selling out-of-stock products or even restocking your worst-performing SKUs.

All those issues beg the question: Which 3PL inventory management system is right for your business? This post will highlight the key benefits, challenges, top software available, and best practices for improving 3PL relationships.

What is 3PL inventory management?

Third-party or 3PL inventory management is the practice of outsourcing the storage, tracking, and distribution of goods to external companies.

Instead of managing its own warehouse and inventory, a retail business hires a specialized 3PL company to do it for it. This can save time and money and let the business focus on creating, marketing, and selling products.

3PL inventory management software is a specialized tool for managing the flow of goods within a business. Most software can track products, manage orders, and ensure accurate and timely delivery.

The goal of 3PL inventory management is to streamline inventory replenishment, lower costs, and scale up operations.

📚 Read: Inventory Management: Everything You Need to Know (2024)

Challenges of 3PL inventory management

No matter if you’re setting up a retail shop or running a booming online store, maintaining an efficient 3PL inventory management system has its challenges.

Inaccurate stock levels

One big challenge of 3PL inventory management is keeping track of exactly how much stock is available. When orders are fulfilled by a 3PL, you don’t always see what’s selling well, which products to buy in larger quantities, and what products are underperforming and need to go on sale.

Sometimes, the numbers can be wrong due to mistakes in counting or updating the system. Merchants may think they have more or less of a product than they actually do, causing issues with orders.

For example, your site may list a product as in stock when you don’t have any available. Shoppers then purchase the product before realizing it isn’t available, causing issues with customer satisfaction.

Lack of visibility

Sometimes, retailers don't have a clear view of their own inventory. This means they can't always see where their products are or how they're moving through the entire supply chain. This lack of visibility can make it hard to make informed decisions and respond quickly to changes in demand.

Increased costs of outsourcing

While outsourcing inventory management to a 3PL can save money in some areas, it may also increase costs. Zeroing in on the third-party logistics sector, the 2023 3PL Warehouse Benchmark Report shows that managing costs ranked as the top business challenge, and nearly half (48%) of respondents will need to overcome it in 2024.

These costs can come from the fees charged by the 3PL provider, the need for advanced tech, and rising storage costs. In 2023, asking rents for US distribution and warehouse space reached a record-high $9.72 per square foot in 2023, up 20.6% year over year. Warehouse worker wages rose by 7.4% in 2023 too.

Benefits of 3PL inventory management software

To run a profitable and scalable retail business, you need to have products available when customers are ready to buy them. Inventory management software can enhance your retail business in several ways:

Real-time visibility

With 3PL inventory management software, companies get real-time access to their inventory data––you can see exactly what's happening with your products at any moment.

Real-time visibility helps you make better stocking decisions, respond quickly to changes, and keep customers informed about their orders.

Accurate inventory tracking

Rather than guessing your inventory levels, you’ll know exactly how much stock you have available for sale. Solid inventory management software updates inventory levels when a product is purchased or returned.

Accurate tracking ensures stock levels are always up-to-date, reducing the chances of errors like overstocking or stockouts.

Faster order fulfillment

Customer expect their orders to arrive fast. Some 62% only want to wait up to three days for a package. Inventory management software can help you meet these increasing customer demands.

For instance, software can automatically generate purchase orders when stock levels fall below a certain threshold, so popular items are always in stock and ready to be shipped. Plus, most software integrates with order management systems, enabling seamless order processing across different sales channels.

Some software can even provide insights into the best ways to organize inventory in the warehouse, making it easier and faster for staff to pick items for orders.

Scalability

As your retail business grows, managing inventory from a spreadsheet isn’t always feasible. Manual inventory management leaves too much margin for human error and is too simplistic for growing businesses.

Good inventory management software lets you scale up or down your operations. When you have a clear idea of your inventory needs, adjusting your storage and logistics capacity is easier.

🧠Learn: 8 Benefits Of Outsourcing Order Fulfillment for Your Retail Business

3 best 3PL inventory management systems

To help you choose an inventory management system that’s for your business, we’ve narrowed it down to three different

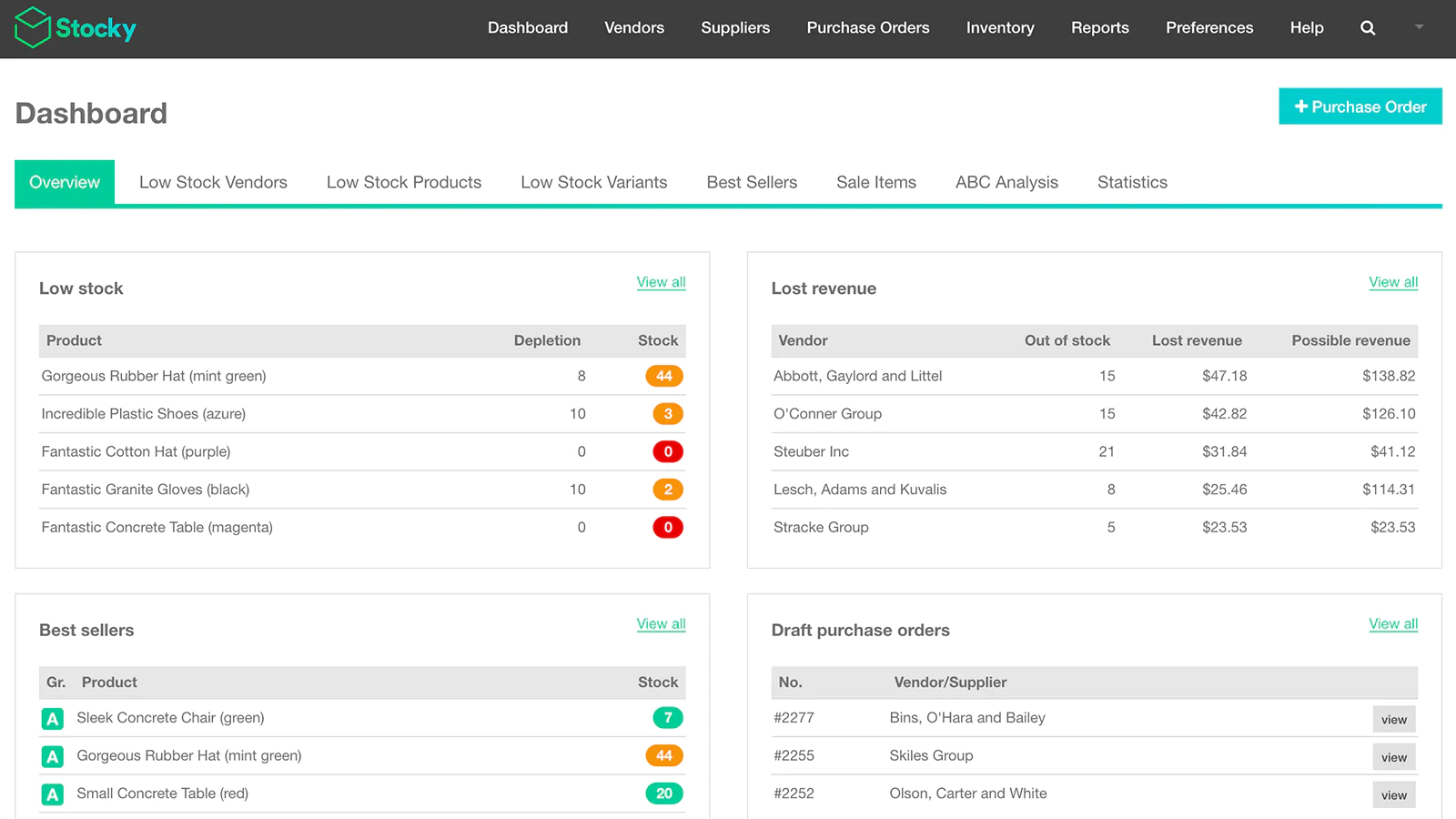

1. Stocky

Stocky is Shopify’s inventory management system. It's the go-to tool for Shopify merchants to track stock levels, create and manage purchase orders, and gain valuable insights through robust analytics. It's known for its user-friendly interface and robust features.

Stocky also syncs inventory across multiple online channels like Amazon and eBay.

Top features:

- Streamline your stock replenishment process.

- Easily handle returns, damages, or discrepancies.

- Predict stock needs to avoid overstocking or stockouts.

- Keep all your supplier info in one place.

- Manage different product sizes, colors, and more.

- Access detailed reports for informed decision-making.

👉 Get the Stocky Shopify app for your store.

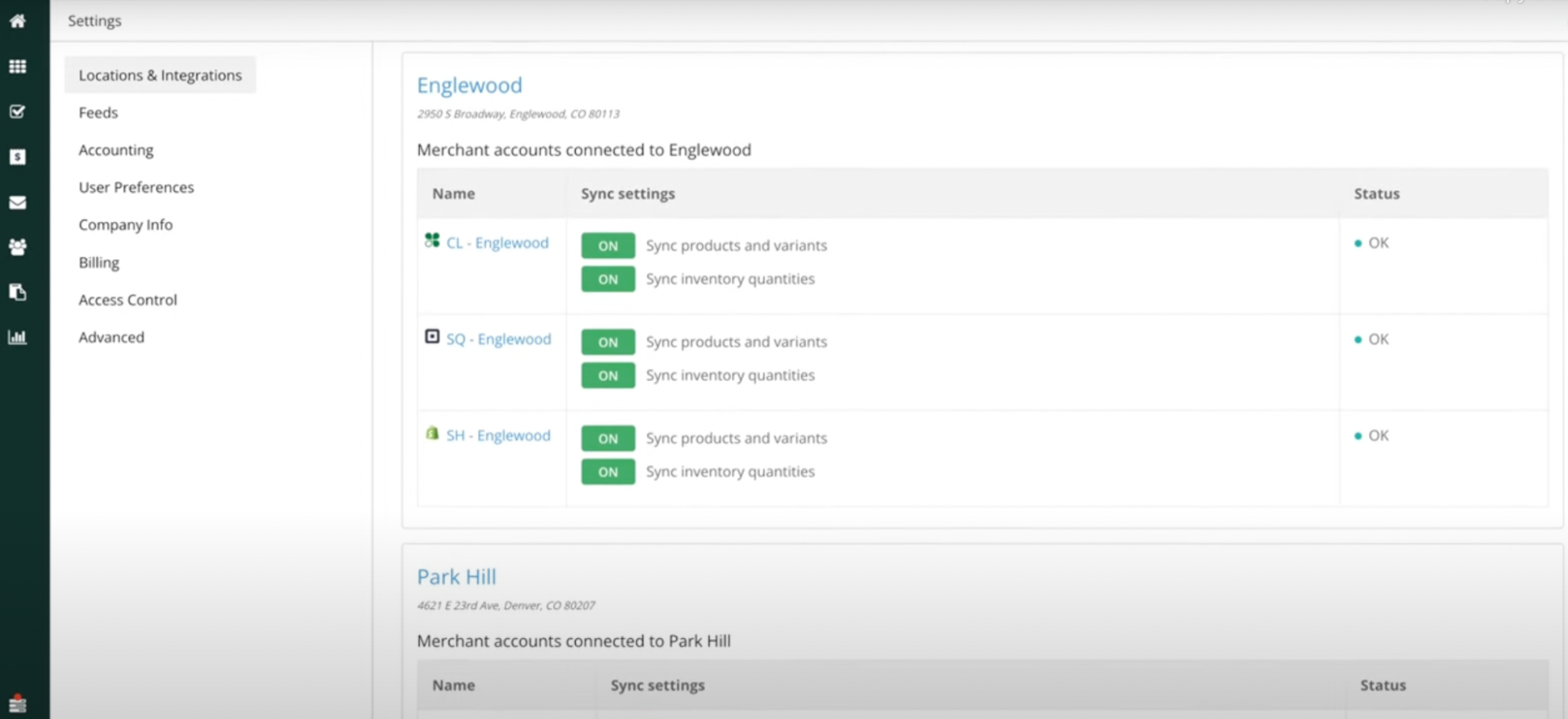

2. Thrive by Shopventory

Thrive by Shopventory stands out for its accurate inventory data. It comes with a comprehensive collection of reporting tools that shine a light on what’s happening with your stock at every stage of the journey. For instance, a quick glance shows how many items you have available, how this season compares with last year’s, and how profitable a specific product range is.

There are some automation capabilities, including purchase orders based on stock levels and inventory balancing across locations. There’s also a mobile app barcode scanning for checking stock from your phone.

Top features:

- Track inventory levels in real-time

- Organize and manage warehouse operations

- Automatic purchase orders

- Integrates with Shopify, Shopify POS, Clover, and Square

- Detailed reports and analytics

Jara Moser, head of marketing at Thrive, explains the best way to work with a 3PL without sacrificing the ability to optimize your entire business, from order management to fulfillment, is with an inventory management system.

“Thrive’s app ensures every aspect of your business benefits and supports each other with tools like stock counts, sales and inventory reporting, and reorder min/max levels,” she says.

“Our platform provides a lot of reporting data around product sales velocity, which helps merchants make buying and pricing decisions. We also help with things like tracking supply chain timings so they don't run out of stock before they can get replacement goods received.”

👉 Download Thrive by Shopventory in the Shopify App Store.

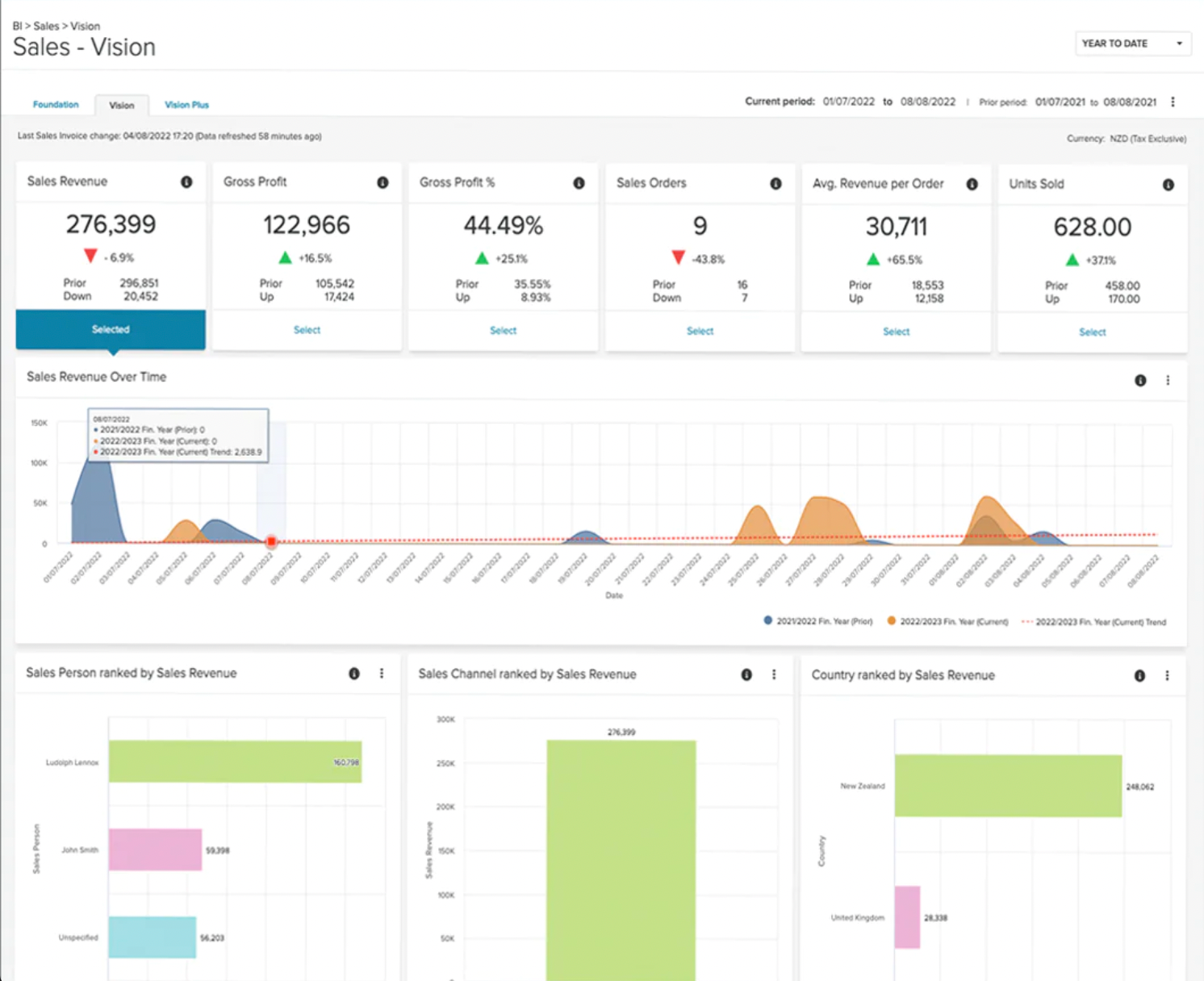

3. Unleashed

Unleashed is a powerful inventory management system designed for better stock control and supply chain operations. The platform has plenty of features to help you manage inventory more effectively and make informed decisions.

Top features:

- Get instant visibility into stock levels and movements

- Easily manage inventory across multiple locations

- Track products by batch or serial numbers

- Integrates with accounting platforms like Xero and QuickBooks

- Manage sales and purchase orders

- Access a range of reports to analyze inventory performance and profitability

Greg Roughan, content manager at Unleashed, explains how the software’s API keeps the right data automatically flowing to 3PLs.

“Great data sharing is the biggest factor in a successful 3PL relationship. You want all your customer details, tracking numbers, and billing information flowing into one place–i.e. Unleashed–then the appropriate data automatically flows through to your 3PL, which is easy to set up via Unleashed’s API.”

👉 Download Unleashed in the Shopify App Store.

5 best practices for 3PL inventory management

Regardless of the 3PL inventory management system you choose, these best practices will improve your collaboration with 3PLs.

Ensure returns functionality

Returns are a part of selling goods online. Failing to offer returns may lower customer satisfaction and leave money on the table. Yalu Xu, a marketing specialist at Momo Lifestyle, explains that your chosen 3PL needs to offer returns so you’re not unnecessarily losing money.

“Retailers can recover significant value when returned products are sent back in unused condition. In these cases, you can put returns back into your stock and sell them again,” she says. “Any 3PL inventory management software should have this service available so you don’t lose money unnecessarily from customer changing their mind.”

Communication

Frequent communication with your 3PL provider keeps everyone in the loop and ensures details don’t get lost in the mix. Xu recommends creating a WhatsApp group with your 3PL provider.

"Having a WhatsApp group is key for small emergencies that arise from time to time, such as when another service provider or warehouse does not ship your order on time. In these situations, it's important to be able to count on your 3PL provider to ship out the order for you before any shipment deadlines."

Set clear expectations

Setting clear expectations early on helps both parties understand what’s realistic. Defining roles, requirements, and processes at the outset helps set up the relationship for long-term success.

Shawn Stack, the founder and CEO of Hallmark Timmins, explains you should put your expectations in writing before beginning a partnership.

“At the start of the partnership, have an in-depth discussion about each party's responsibilities, performance metrics, reporting needs, and protocols for resolving issues. Put service-level agreements in writing to create accountability on both sides,” he says.

“For example, I once partnered with a 3PL to manage our shipping and logistics operations. By outlining upfront the required order accuracy rate, expected transit times, and protocols for reporting and resolving discrepancies, we created transparency and avoided misunderstandings down the road.”

Understand the shipping framework and costs

Define your shipping methods and costs before committing to 3PL inventory management, Will you cover shipping costs? Or will you use the 3PL’s carrier shipping rates?

Shipping rates vary depending on the location of the buyer in relation to the 3PL warehouse, so it’s important to understand the costs different purchases incur in advance.

Yalu Xu of Moma Lifestyle recommends comparing shipping costs for several test locations, “Make a comparison of different shipping speeds (standard, expedited, and 1-2 days) for each product based on the shipping price to send to four locations. For example, in the US, these could be New York, Florida, Texas, and California. Doing so will help you understand the real costs of shipping in advance to ensure you choose the best option.”

Conduct regular audits

Regular audits are like inventory check-ups. They ensure that the number of products you think you have matches the number of products you actually have.

Here’s how to do them:

- Schedule regular audits: Plan to do audits often, like once a month or once a quarter, so you can catch any issues early.

- Use different methods: Sometimes, count everything (a full audit). Other times, just count a few items (a cycle count).

- Check for accuracy: Compare what you counted to what your 3PL system says. If there's a difference, work with your 3PL to figure out why.

- Update records: If you find mistakes, update your records to make sure they're right.

- Identify patterns: The same repetitive mistakes indicate a bigger problem to fix.

Master 3PL inventory management for your store

Now that you know what to look for in a 3PL inventory management system, you’re ready to search for the right solution for your business.

Whether you’ve just opened your first online store or are expanding operations globally, 3PL inventory management can help your business scale and succeed.

3PL inventory management FAQ

How do you manage a 3PL warehouse?

- Regularly communicate with your 3PL provider to discuss expectations and any changes in inventory or order volume.

- Set key performance indicators (KPIs) to measure the efficiency of your warehouse operations.

- Use the 3PL's warehouse management system (WMS) for real-time tracking of inventory, order processing, and reporting.

- Conduct regular audits to check inventory accuracy and make sure the 3PL is meeting agreed expectations.

- Collaborate with your 3PL to make receiving, picking, packing, and shipping better.

What are the benefits of using 3PL?

Using a 3PL offers several benefits for your business:

- Saves time: Outsourcing logistics lets you focus on core competencies.

- Cost-effective: 3PLs can provide services at a lower cost due to their expertise and scale.

- Flexibility: Scale your logistics up or down based on your business needs.

- Expertise: Benefit from the 3PL's knowledge in logistics and supply chain management.

- Tech: Access advanced tech for better inventory and order management.

What is inventory control in logistics?

Inventory control in logistics means tracking your products to ensure you have the right amount in the right place at the right time.

Inventory control involves:

- Managing your stock levels

- Ordering new products when needed

- Making sure orders are sent out correctly

Good inventory control prevents stockouts and overstocking, which can save you money and keep your customers happy.

How do you manage inventory in logistics?

Managing inventory in logistics involves six key steps:

- Track inventory: Use software to keep an eye on stock levels and movements.

- Forecast demand: Predict future sales to determine how much stock you need.

- Set reorder points: Decide when to reorder products based on stock levels.

- Optimize storage: Arrange your warehouse to make picking and storing items efficient.

- Regular audits: Check your inventory regularly to ensure accuracy.

- Analyze data: Use data from your inventory management system to make informed decisions.

What is a 3PL inventory management system?

A 3PL inventory management system is a tool used to manage and track a retail business’s inventory. This system provides:

- Real-time tracking: Monitor stock levels and movements as they happen.

- Order management: Process orders from receiving to shipping.

- Warehouse organization: Manage how goods are stored and moved in the warehouse.

- Integrations: Works with other systems like ecommerce platforms and shipping services.

- Reporting: Provides insights into inventory performance.