Scaling an international ecommerce brand is no small feat. Currencies, languages, and product preferences differ from country to country, but one of the biggest hurdles with international expansion is foreign warehousing.

In today’s global supply chain, international warehouses are your hubs. They ensure timely delivery of goods to far-flung customers at an affordable cost and with minimal shipping challenges.

Moreover, international order fulfillment is a key extension of your brand identity—giving your international customers the complete brand experience instead of getting a generic one from Amazon.

While there are challenges inherent in managing inventory distribution across multiple global locations, the benefits of international warehousing for your supply chain, shipping, and delivery time are crucial to growing your sales across borders.

What is an international warehouse?

An international warehouse is a strategically positioned facility in a foreign country that stores and distributes goods for global trade. It acts as a central hub for managing inventory, fulfilling orders, and optimizing logistics across borders, facilitating efficient international supply chain operations and expanding global business reach.

Take it from Ben Hyman, co-founder and CEO of Revival Rugs, a retailer with warehouses in California, Turkey, Morocco, and India. He says, “This allows us to sell directly to the consumer, cutting out the middleman. When someone buys one of our products, the process is smooth, transparent, and affordable. Steep markups and costs that don’t add value are eliminated. We credit that to our international warehouses.”

The 4 types of international warehouse

Public warehouse

A public warehouse is open for any business to use, at the discretion of the warehouse operator. It’s usually the first choice for ecommerce businesses looking for an international warehouse, since they can pay a fee to access existing storage and fulfillment options outside their own country, without building the nearest warehouse themselves.

Private warehouse

Private warehouses, on the other hand, are owned by private companies. Think of them as extensions of your business. If your headquarters are in the US, you could build a private warehouse—solely for your own use—in another country to cater to international shoppers.

Bonded warehouse

A bonded warehouse is a place for businesses to store inventory set to be imported or exported. Also known as a customs warehouse and run by the local government, it’s a way for businesses to bring products in or out of the country without paying tax or import duties.

Distribution center

An international distribution center is different from traditional warehousing. A warehouse stores goods, while distribution centers can do additional tasks like fulfill and package orders. Some operators offer both services under the same roof.

Why you need to use international warehouses

Shippers and players in the international logistics business are under pressure. Increased energy prices, fluctuations in supply, demand for transport capacity, and delays in port trans-shipment are some of the lingering issues impacting supply chains trends today.

That’s why the global warehousing and storage market is expected to reach $634 billion by 2028. More brands are using international warehouses to continue production through the year, sell their goods, and predict future demand.

International warehouse space means cutting both ecommerce shipping costs and times, giving you an advantage with positive customer experience in an increasingly competitive delivery market. For the most part, warehouses located internationally will be in global trade hubs like Hong Kong, the Middle East, Los Angeles, and Houston.

No matter where your headquarters and manufacturing are located, strategically placed warehouses let you easily cross borders throughout Asia, Europe, and North America.

How to choose an international warehouse

The hard part in setting up an international warehouse revolves around finding a good partner and picking the right location.

1. Diversify your locations

Traditionally, choosing an international warehouse location has come down to figuring out where most of your international customers are based.

In an interview with 1-800-DTC, Ammar Moiz, founder of Mayple, said, “We consolidate the shipment with all the brands making their way to our distribution center in Dubai. This makes it not only cost efficient for everyone involved, but also better for the environment.

“Our brands ship their product to a local distribution center out in the US, the UK, or Australia—wherever the brand may be. From there, we arrange for the shipment to our distribution center in Dubai. From there, we fulfill orders to consumers all around the world.”

Centralized fulfillment centers represent single points of failure that can bring your business to its knees. You can ensure you serve your customers best by having a more diversified fulfillment strategy available to draw on in a crisis.

2. Consider shipping laws

When choosing where to partner, you also need to consider import and shipping laws. Check the legality of importing a product in a certain region through designated government websites.

Did you know, for example, that the FDA considers all sunglasses medical devices and that your manufacturer has to be FDA approved? It’s always important to check import regulations around a product before bringing it into a country.

“To give you a small example of the complexities we manage, certain supplements might be banned in New Zealand, because they don’t allow for more than 1,000 IUs of vitamin D, which is pretty standard for the rest of the world. We make sure those logistical nuances are managed so we don’t have negative customer experiences downstream,” says Moiz.

It’s important to have the full control of your inventory and shipping worldwide that international warehouses offer. Think of the frustration your customers feel when they experience delayed, stolen, or damaged packages at a time when so many people are relying on delivery service.

Evaluate the challenges that come with managing different shipping rules and regulations put in place by different countries.

-

Can you get packages into quarantine zones from outside?

-

Do you want

coming back to your central warehouse from a foreign hot zone?

-

Are you even able to take returns from these areas?

3. Check policies and procedures

Locations and costs aren’t the be all and end all of your decision making. When evaluating warehouses, the lowest price and best location won’t protect you from failure if your business isn’t well-suited for a particular warehouse.

Specific policies and procedures dictate the general conduct of a warehouse’s operation. Such policies should be clearly spelled out, and you need to check the warehouse’s track record of past clients to see how they’ve dealt with conflicts before. That includes:

-

Management policy and procedures guideline

-

Health and safety measurement

-

Human resources management

-

Security and pest control

-

Maintenance and cleaning

-

Quality control

-

Record keeping and reporting

-

for returns

-

Disposal of obsolete and damaged goods

Though these procedures should provide checks and balances, they must also have the flexibility to cater to unique situations. A good warehouse is focused on the end goal of a procedure, so it’s common practice to limit the level of details in the procedures document.

4. Know your storage requirements

To understand your exact storage requirements, you’ll need to know the details of how your product is stored—be that on pallets, shelving, or temperature-controlled warehousing—and your expected sales volume in the area.

For instance, if you know you’re going to sell a lot of products in China during the Lunar New Year in February, it would be smart to move more inventory to that region to prepare for the sales season.

Other storage-related requirements on your international warehouse checklist include:

-

Characteristics of goods to be stored

-

Equipment available to handle the goods

-

Estimated duration of storage needed

-

Need for third-party logistic activities

-

Size of the warehouse

-

Past clients the warehouse has worked with

-

Security of the warehouse

-

Storage requirements of your company

When scouting international warehouse options, focus on a layout that facilitates growth and allocates you more space as you need it. You want your business to scale with the warehouse, instead of having to find a new one every year or two.

5. Check international warehouse management system capabilities

Make sure your partner is well-equipped to scale as your business does, using warehousing technology like:

-

RFID scanners

-

Collaborative robots, like

“As an integral part of your 3PL partnership, the key thing to look at in an international warehouse—beyond, services, space, and pricing—is what technologies they use,” says Robin H. Smith, co-founder of VL OMNI, another Shopify Technology Partner.

According to Robin, there are four levels of players:

-

The big brands who are heavily invested in solid technology

-

Those that use off-the-shelf software

-

Those that have built it themselves

-

Those that have limited technological experience and often run their businesses on spreadsheets

Robin says international warehouses that fall into the last category play on price: “Make sure your partner is giving you a clear picture of what their technology is, who supports it, and how flexible it is. Only then begin negotiating on price.”

Software should allow either the customer or the 3PL to quickly identify orders that need special attention or to make simple changes such as address changes, add or subtract an item, or add packer notes easily, all with a unique, secure login to the client's private 3PL account. Those changes need to be automatic, tracked, and instant,” says Adam Rosenberg, Director of Operations at ShipHero, a Shopify technology partner.

6. Ask for references

There’s a lot that goes into choosing a global warehouse. Minimize risk later down the line—and avoid choosing the wrong partner—by asking each of the warehousing services on your shortlist for unbiased references.

“First, visit their facility to see what kind of products they’re shipping,” says Rosenberg. “While on site, take note of the products that are similar to you and ask if you can speak to a few of the business owners—the specific companies and brands you’ve identified that 3PL supports. Asking the 3PL to provide a reference is not reliable because they might have you speak to a client that is really small or a friend or relative that will only say good things.

“Second, find out what their procedures are for different items that are important to your business. One example is asking how they handle changes to an order, such as changing a customer’s address. If their answer is ‘Email us’ or ‘Call us,’ that's a red flag!”

7. Regularly visit the warehouse

The right international warehouse grows with your ecommerce business. Attend regular check-ins with your partners to make sure that’s possible. This warehouse checklist gives you a starting point for things to look at:

-

Is the building kept clean and tidy?

-

Are storage areas well lit and easily accessible?

-

Are workers treated fairly? Do they look happy?

-

Are health and safety measures in force?

-

Can you see fire alarms, extinguishers, and fire doors?

-

Is technology in place to speed up the storage and fulfillment process?

8. Look for third-party logistics services

Setting up international warehouses can be more complex than setting up multiple storefronts or global marketing campaigns. You will not only face different rules and regulations in each country, but also potential language barriers and cultural differences.

Working with a third-party logistics (3PL) company at an international warehouse will optimize your international logistics ability while helping optimize your supply chain. You will cut out the cost of duties on your products when they are shipping locally, which should make your international shipping smoother.

When looking for a 3PL partner, evaluate whether you need reverse logistics solutions included in the service.

The reverse logistics provider receives and approves the return based on your qualifying criteria. The money is refunded to the customer within a few days, and the returned product is back on the warehouse shelf to be resold. It reduces the cost of shipping, is better for the environment than shipping individual packages to your HQ, and is faster to process.

Either way, Robin H. Smith, co-founder of VL OMNI, has a word of warning: “Too often we see customers locked into a 3PL with no way to move away. The desire to move usually happens when a company starts to scale and they need multiple 3PLs in different countries, or when the existing 3PL provides poor service. “Steer clear of any 3PL that wants to take over and control all the channels in your business. You have to ask yourself: What is their core business? Is it being a 3PL warehouse or an agency?”

The costs associated with international warehouses and fulfillment

The costs associated with warehouses are typically broken down by your warehousing partner between actual warehouse and fulfillment costs.

Warehousing costs

Warehousing costs include things like the lease, employee salary, equipment costs, and the electrical bill. They are usually included under the umbrella of a total warehousing fee.

Most warehousing partners will have minimum monthly fees that they charge their clients regardless of whether the client has had a slow month of fulfillment, though you may get a discount on larger orders.

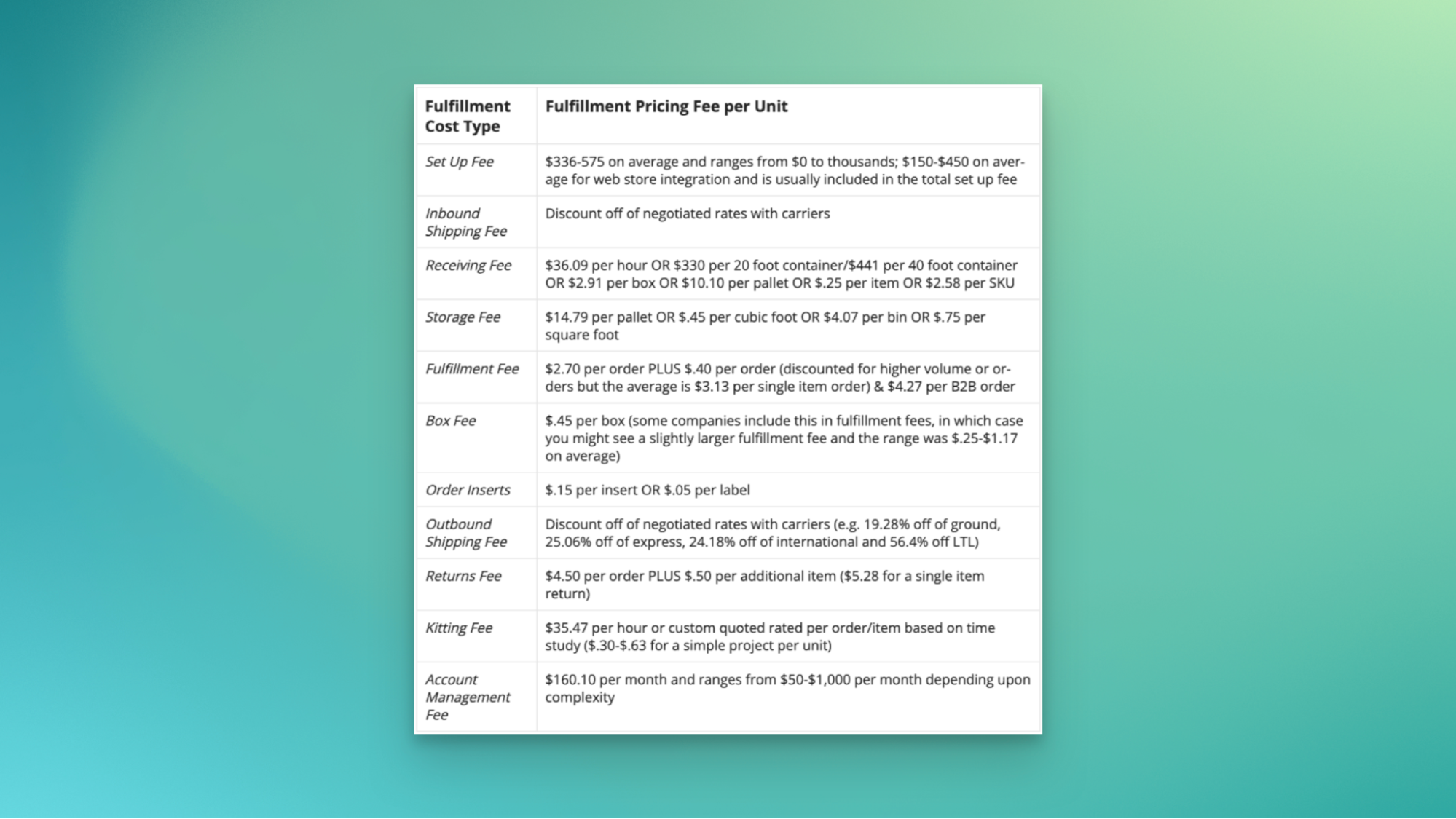

Fulfillment costs

Fulfillment costs, on the other hand, are billed when items begin moving. A 3PL will bill you when it receives inventory, package and ship orders, and handles reverse logistics. Fulfillment companies share estimated costs to factor in to your international warehousing budget:

International customers and global warehouses

With an international warehouse, you can create a better experience for your customers abroad while drastically improving your shipping times. The worst-case outcome would be not ultimately needing the space because your international sales don’t spike as you expect.

But the real magic moment will come when your international warehouse feels like a fully integrated part of your business, even if it’s thousands of miles away from your home base.

Read more

- Ecommerce Usability 101: Are You Making it Difficult For Visitors to Purchase?

- Hypefest 2018: O2O Examples from the Forefront of Marketing & Retail

- What Conversion Experts Wished You Knew About Optimization

- Why Are You Still Paying Over $1 Million for an Ecommerce Site? The Answer May Shock You

- 10 Segments to Make More Money with Your Black Friday, Cyber Monday Emails

- Is Your Agency 'The One'? An Inside Scoop on Finding a True Partnership

- Holiday Automation with Flow: 10 Ways to Make Black Friday Easier, More Profitable

- Native Advertising for Ecommerce: From Content Discovery to Scaling Sales

- What to Do After You've Lost a Loyal Customer

- Instagram Influencer Marketing in Ecommerce: Everything You Need to Know

International warehouse FAQ

Where is the Shein warehouse located?

Fast-fashion retailer Shein doesn't have just one centralized warehouse. Instead, it operates multiple warehouses around the world, with the HQ in Guangzhou China. Shein also has warehouses in Europe, the US, and Asia.

Who owns the most warehouses?

The United Parcel Service (UPS) owns the most warehouses in the world. The company, known for delivering packages around the world, maintains more than 35 million square feet of warehousing and distribution facilities in 120 countries.

What is the biggest warehouse in the US?

The biggest warehouse in the US is Amazon’s Distribution Center in Mt. Juliet in Tennessee. It spans over 3.6 million square feet and employs over 3,000 full-time and part-time employees.

What are the benefits of an international warehouse?

The benefits of an international warehouse include increased efficiency in global supply chain management, reduced shipping costs and transit times, and better customer service by being closer to various markets.

How do I set up a distribution warehouse?

To set up a distribution warehouse, first identify the ideal location considering factors such as proximity to customers, transportation infrastructure, and local regulations. Then, design the warehouse layout for optimal space utilization and material flow, and implement warehouse management best practices to streamline operations.

What is the difference between a warehouse and a distribution warehouse?

A warehouse is primarily used for storing goods, while a distribution warehouse is specifically designed to facilitate the efficient movement and distribution of products to customers or other business locations. Distribution warehouses typically have advanced systems for efficient inventory management, order processing, and transportation logistics.

What is the average cost of a distribution warehouse?

The average cost of a distribution warehouse depends on factors such as location, size, construction type, and required features. In general, costs can range from $50 to $300 per square foot for construction, with additional expenses for sourcing land, utilities, and equipment.