Illustration by Diego Blanco

Unless you have the bandwidth to focus on ecommerce logistics, this essential but complicated element can be a painful drain on your team’s resources.

Ecommerce business owners don’t always have the luxury of housing stock in brick-and-mortar locations.

That means you’ll need to figure out the logistics behind how an online order gets picked, packed, and shipped to the person buying it—regardless of where they (and your products) are.

So, how do you deliver the same top-quality experience when you’re scaling? This guide shares how to fine-tune your ecommerce logistics process and prepare your business for an influx of online orders.

What is ecommerce logistics?

Ecommerce logistics is the management and coordination of various activities involved in fulfilling online orders. It encompasses inventory management, order processing, warehousing, packaging, and shipping. Ecommerce logistics ensures efficient and timely delivery of products, optimizing the supply chain to meet customer expectations in the digital marketplace.

Having a well-thought-out logistics process isn’t just a nice-to-have. Ecommerce brands are seeing fast and efficient logistics as a competitive advantage. Some even report huge risk to their business if their logistics process doesn’t meet customer expectations.

Components of the ecommerce logistics process

Order fulfillment

Order fulfillment refers to receiving, processing, and delivering customer orders. Quality, order accuracy, and getting orders out of a fulfillment center in a timely fashion are the most important capabilities you need to look at when you’re talking to potential vendors.

It’s a critical component of ecommerce logistics because it directly affects the customer experience and your reputation. If you can’t fulfill orders on time, you’ll struggle to meet the demands of online shoppers.

Nothing disappoints the consumer more than screwing up the basics. No amount of wow factor, and no amount of marketing buzz will ever overcome logistical nightmares in an ecommerce supply chain. Customers want confidence in the fact their order will arrive as and when intended.

Example: You receive an order through your ecommerce platform, pick and pack the items in your warehouse, and then ship them to the customer.

Inventory management

Inventory management is exceptionally important and also, frankly, a science. How much buffer to have and how much of a given product to have in stock varies based on the retailer’s situation, what they sell, and where they find themselves financially.

Excess inventory is bad, right? It ties up cash you could use more productively in other areas of your business. But on the flip side, we’ve all been in situations where we’ve been shopping online and find the thing we want to buy but, unfortunately, there are no units on hand.

There’s a lot of information online about how to evaluate how much inventory to hold, how to calculate and analyze your inventory turn rates and turnover days, and so forth. But it boils down to a few variables:

How much does your inventory cost?

How much do you typically have on hand at any one time?

How predictable is your demand?

How do you replenish your inventory?

The simpler those variables are, the more feasible it is for you to manage your inventory. The more complicated they are, the more difficult it will be—which means it might make sense to consult with experts.

Example: An inventory management system integrates with your ecommerce store. It automatically updates stock levels when orders are placed and can trigger reorders at certain levels.

Warehousing

Warehouse management is how and where you store products before they are shipped to customers. Online retailers use warehouses to scale fulfillment and take on more orders, without sacrificing delivery speed and accuracy.

Example: A warehouse management system helps plan, organize, staff, and control available resources in your warehouses. It integrates with your ERP and can provide advanced reporting capabilities to optimize workflows. Many retailers partner with a 3PL and use its warehouse to make supply chain management easier.

Returns and reverse logistics

Ecommerce returns and reverse logistics involve handling and processing returned products, either due to customer dissatisfaction or damage during transit.

Ecommerce logistics is more than getting your product to an end consumer. You’ll need a process in place to handle movement of products in the opposite direction, known as reverse logistics.

Returns plague ecommerce retailers—often through no fault of their own. Customers are honest with the fact they buy variations of a product with the intent of returning them.

A popular reverse logistics strategy is allowing customers to return things they bought online, in-store. “It’s a far better consumer experience, because it doesn’t involve printing labels, cardboard boxes, and, most importantly for shoppers, it doesn’t involve waiting to get your money back,” says David Sobie, CEO and co-founder of Happy Returns.

Example: A customer initiates a return through your ecommerce store. You seamlessly receive and inspect the returned product, then process a refund or restock the product for resale.

Types of logistics management

Third-party logistics providers

Third-party logistics (3PL) providers act as the intermediary between a completely hands-on and hands-off approach. In this case, you’re still in control of the products you’re selling through your ecommerce site. The only difference is that your products are stored, labeled, and packed in a third-party distribution hub and fulfillment center.

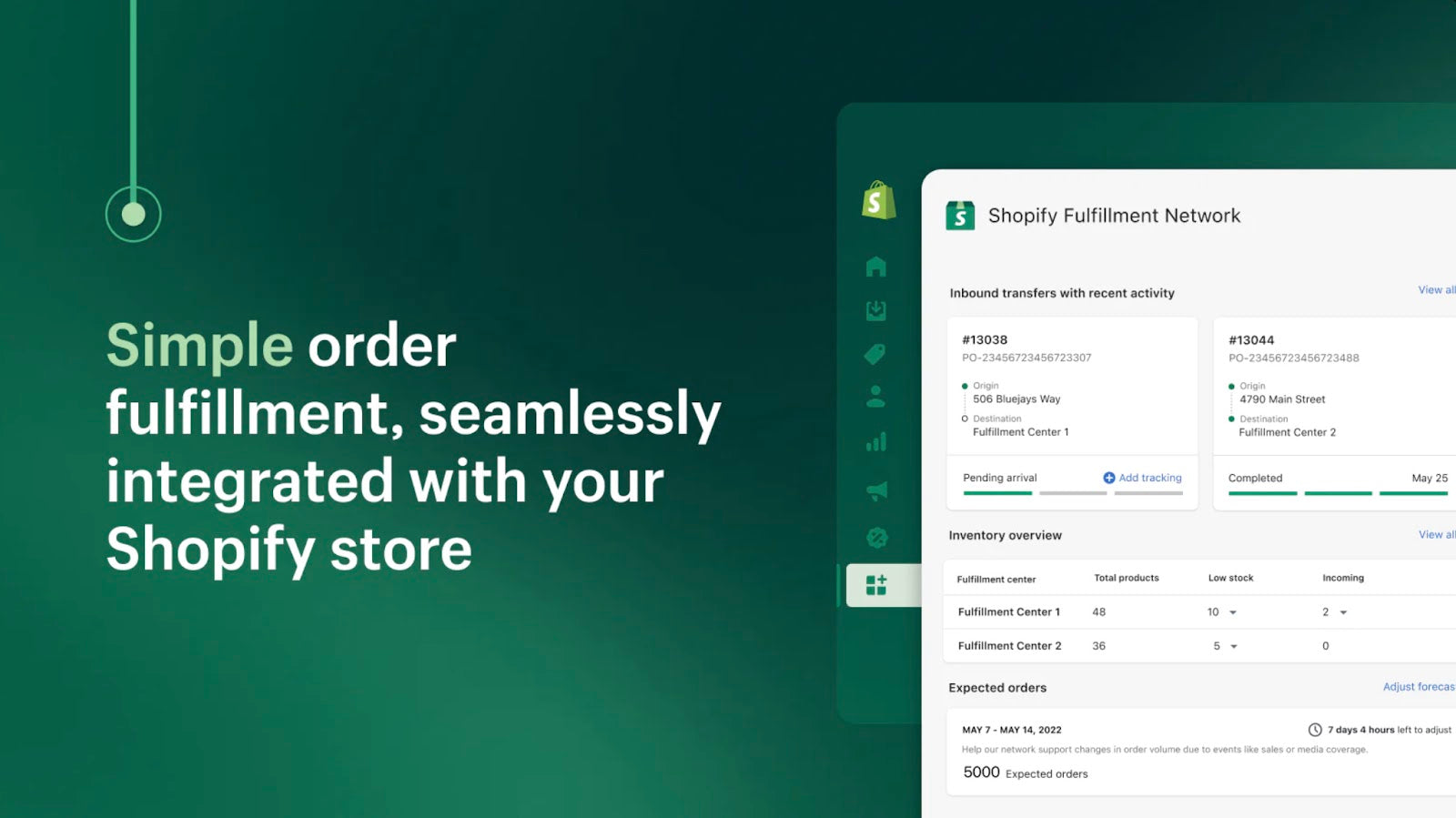

One of those is Shopify’s Fulfillment Network. These centers are dotted all over the country and act as the home for your unsold stock.

When it’s purchased by a customer online, staff (and their robotic support) in the fulfillment centers pick, pack, and ship your products to your customers. It’s a time- and cost-saving way to take the logistical nightmare out of selling online.

And if you’re wondering how you can find the perfect 3PL partner for your business and customer needs, we have a checklist that can help. You’ll find a set of questions to ask 3PLs to ensure you’re choosing the best possible provider for your needs:

In-house logistics

Companies with brick-and-mortar stores or warehouses can opt to do their own logistics in-house.

In this case, you have a dedicated team that welcomes incoming goods, stores them, and picks them out when an online order is made. You’ll need to partner with a shipping carrier—like FedEx, USPS, or DHL—that collects the orders and delivers them to a customer.

Dropshipping

The logistical process for retailers using a dropshipping business model is much less complex. They don’t touch the items they’re selling through their online stores. As soon as an online order comes through, it’s sent to a third-party provider who picks, packs, and ships it.

Learn more: What Is Logistics Management?

Ecommerce logistics companies

Shopify Fulfillment Network

Don’t want to deal with the logistics process of shipping products to end customers? Shopify Fulfillment Network will pick, pack, and ship orders as soon as they’re generated through your ecommerce platform or point-of-sale (POS) system.

Retailers can see real-time analytics on their inventory right from their Shopify dashboard. Simply ship stock to a distribution center if you see it running low and you’ll always have stock ready to fulfill new orders.

Each fulfillment center uses collaborative robots that help maintain fast fulfillment speeds and 99.5% order accuracy. Plus, staff working in each distribution center are bound by social and ethical codes of conduct that cover safe working conditions and fair pay.

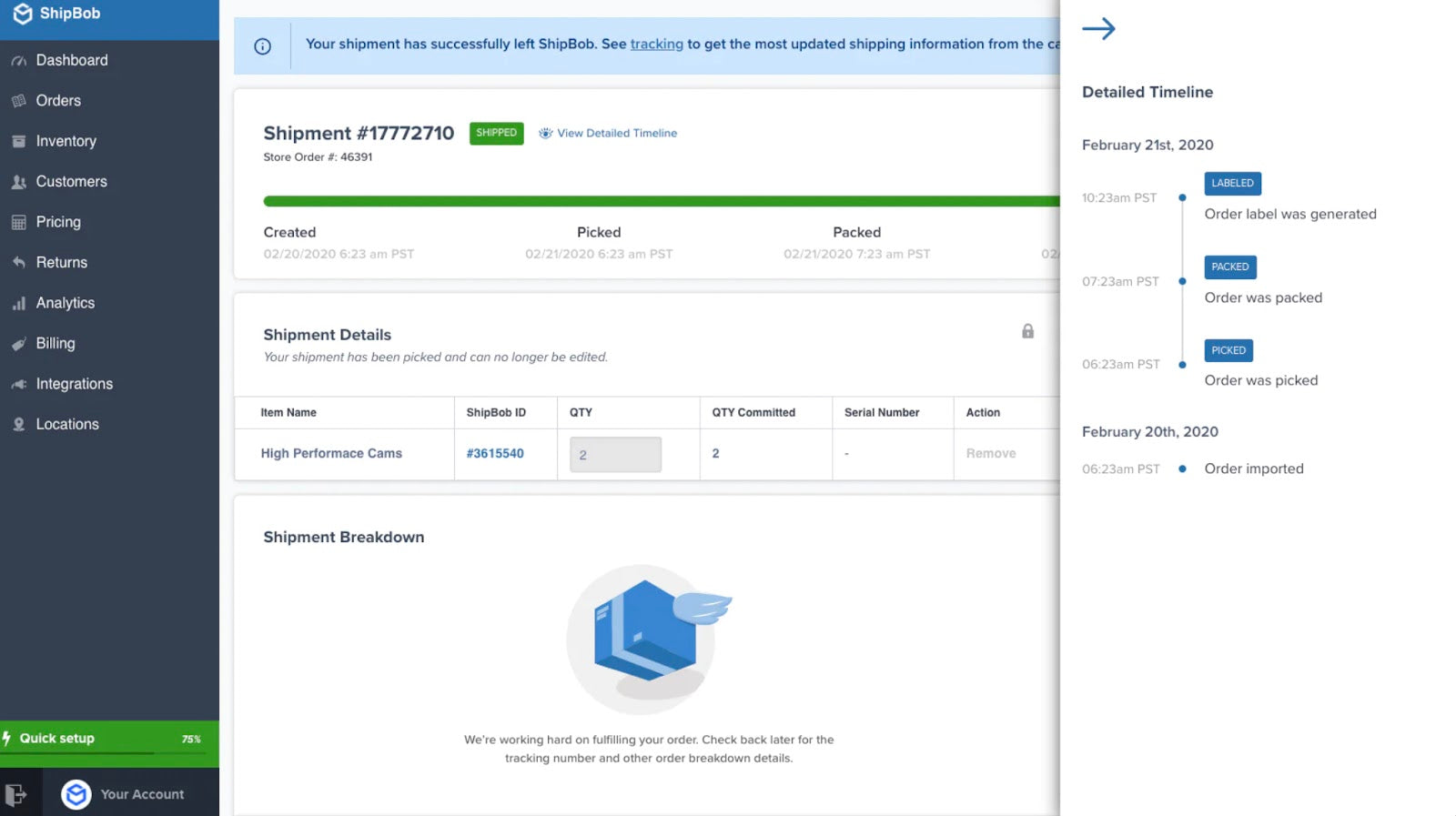

ShipBob

ShipBob is another ecommerce platform that helps direct-to-consumer brands manage their logistics process. It has a global fulfillment network for ecommerce companies to rely on when they’re promising fast shipping to global customers.

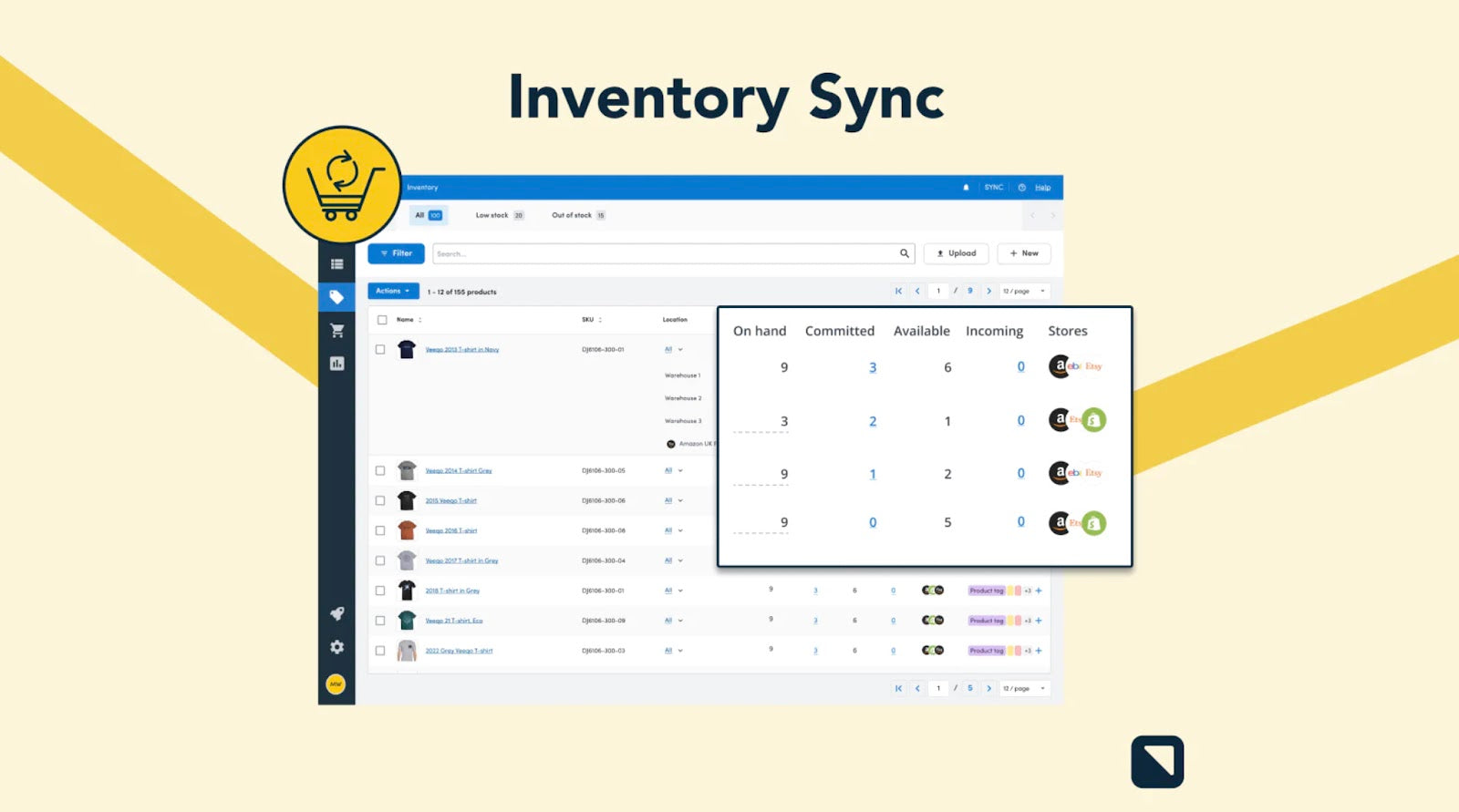

Veeqo

Veeqo makes it easy for retailers to sell across several channels. Its omnichannel inventory and fulfillment services help retailers manage logistics for orders made through their Shopify website and marketplaces like eBay and Etsy.

It acts as a single source of truth for your entire logistics process—regardless of where, what, or how you sell.

6 best practices for ecommerce logistics

Find an ecommerce logistics partner early

Balance value-add logistics with profit

Prioritize free (and fast) shipping

Automate what you can

Regionalize inventory to reduce cost

Diversify your supply chain

1. Find an ecommerce logistics partner early

There are issues to deal with in warehouses, dedicating store space toward housing your inventory, and the complexities in selling to new countries.

Keeping on top of this as a retailer can be extremely difficult. You need an honest dialogue about when logistics is really interfering with the success of the business.

The most obvious advantage is access to capabilities you don’t have. Whether that’s technology, resources, expertise, or new geographies, outsourcing gives you the power to buy-in specialists who do it 24/7.

There are also advantages from a cost perspective. Typically, 3PLs have economies of scale to give you a better cost per unit than what you’re able to achieve yourself. You’ll also have access to infrastructure that you would not be able to deploy by yourself.

Before signing a contract with a larger logistics company, talk with any 3PLs that you could work with to see if they give you a better rate on deliveries. Contracting with two companies can help if one is better at local deliveries and the other is better with long distance.

—Chelsea Cohen, co-founder of SoStocked

2. Balance value-add logistics with profit

Making sure your products are perfectly packaged can increase customer satisfaction, but it’s important to know when these value-added services cause more trouble than they’re worth.

It’s always a good idea to ask about what value-added service capabilities a 3PL has. For example:

What kind of experience and capabilities do they have with kitting?

Are they able to handle custom packaging?

Can they do gift bags?

Can they do custom messages?

Can they work with fancy tissue paper?

Can they work with samples?

Can they personalize the package?

These points are all becoming increasingly important for consumers and retailers. A 3PL provider that can manage these; ask the questions above when you’re questioning potential vendors.

Retailers need to make sure they have the appropriate return on that investment. You always need to balance the operational implications with the marketing wow factor. If the fulfillment process is too expensive or takes too long, it won’t matter how pretty the package is.

3. Prioritize free (and fast) shipping

Offering a no-cost delivery can encourage people to move forward with their shopping. Free delivery is the top reason people shop online.

There are ways to manage free shipping costs, such as having a minimum order size to qualify for it, or offering it only with promotions or select items. Yet with any free shipping option, retailers need an ecommerce logistic solution that is affordable.

Ask your potential 3PL vendors about last-mile delivery—an item’s final journey to the customer. After all, you’ve got the hard task of preventing customers from being incentivized to use Amazon’s same-day shipping.

4. Automate what you can

While you’re investigating the technology a 3PL has to offer, consider whether you can automate any part of the logistics process.

One way to do that is to find an ecommerce fulfillment center that uses robots. According to McKinsey, some companies’ automated pallet-handling systems can halve average shipment-processing times.

It’s estimated that by 2030, many logistics operations performed by third-party service providers can be automated. Examples include product inventory management for stock forecasting and replenishment, picking robots, and multishuttle systems.

Logistics automation doesn’t have to be that complex, though. Fashion retailer GoudronBlanc uses a logistics partner that integrates with its Shopify store. All online orders are synced with the logistics software, but their team manually confirms which orders should be picked, packed, and shipped.

My tip would be to find a way to amend orders, so customers have room to change their mind or correct a mistake they may have made. Though it sounds like an unnecessary step in the world of automation, this allows us to control the flow of orders and change any order based on last-minute requests from a customer.

—Guerric de Ternay, founder of GoudronBlanc

5. Regionalize inventory to reduce cost

Distance equals time and money, and cutting distance down can save a lot of dollars, while maintaining or even improving service levels.

If you’re shipping large volumes to San Francisco, for example, it makes sense to have a warehouse or 3PL partner that can store items in that area. Customers can get free (or same-day) shipping if the product they’re buying is already closeby.

We used decentralized warehouses to disperse stock into high-density areas. This reduces our response time and allows us to react faster to customer demands, without having to double our workforce to keep up with demand.

—Chris Campbell, partner of The Charming Bench Company

6. Diversify your supply chain

While many 3PL vendors have backup plans in place, some issues in an ecommerce supply chain are unavoidable. Employee strikes at a logistics provider, or issues with their own supply chain, can wreak havoc on how fast (and accurate) your online orders are processed.

Parker Russell, owner and CEO of Black Ink Coffee, has experienced issues with his company’s supply chain due to the nature of the business: “Since coffee beans are a traded commodity with their own harvesting seasons, we have found that you need to have many avenues open when it comes to your logistics,” he says.

“That’s why you need a backup plan for your backup plan, to practice proper risk management, and to always keep your employees and staff trained so that they can handle diversities.”

Scaling online orders doesn’t have to be a logistical nightmare

There’s no doubt that the logistics process for online businesses gets more complex as you grow.

Whether you’re handling reverse logistics cross-border or finding logistics services to regionalize your inventory, there are three overarching themes that make your logistics process a success: accuracy, cost, and speed.

Read more

- How to Personalize for Unknown Black Friday Cyber Monday Mobile Visitors

- Ultimate Flash Sale Ecommerce Guide: How to Sell Over $3 Billion on Autopilot

- Ecommerce Customer Experience: Mastering Acquisition and Retention

- How to Block the Ad Blockers & Whether You Should

- How To Maintain A Personal Touch With Customers As You Grow

- Returning Ecommerce Visitors: How to ‘Nudge’ Non-Buyers into Taking the Customer Leap

- Gift Wrapping in Ecommerce: How to Boost AOV This Holiday Season

- How to Create a Brand People Can’t Forget: Purple Mattress on Product, Voice, and Culture

- 11 Ecommerce Checkout Best Practices: Improve the Checkout Experience and Increase Conversions

- What 1-Click Checkout Can Do for Your Small Business

Ecommerce logistics FAQ

What is meant by ecommerce logistics?

Ecommerce logistics is the process of transporting goods for online retailers and customers, from when the order is placed to its final delivery. It involves managing inventory and transportation from the online store to the customer’s doorstep.

What is the general model for ecommerce logistics?

The general model for ecommerce logistics is integrating physical and IT processes, such as warehousing, inventory management, and order fulfillment, to ensure efficient delivery of goods to customers. This model also includes customer support, feedback, and analytics to ensure customer satisfaction.

What is the main purpose of logistics?

The primary purpose of logistics is to plan and manage the efficient, adequate flow and storage of goods, services, and related information from the point of origin to the point of consumption to meet customer requirements.