Illustration by Melanie Peters

Free shipping continues to have a significant influence on purchasing for global shoppers. According to Shippo’s 2023 state of shipping report, over two-thirds of consumers said they wouldn’t consider buying from a retailer that didn’t offer free shipping.

Shipping is one of the most important parts of the online shopping experience—it’s often what dictates whether customers make a purchase or abandon their cart. For fast-growing retailers, free shipping is a chance to streamline checkout and encourage more customers to press Buy.

Successful retail brands need to rethink everything–from where goods are produced to how they’re shipped–to meet these expectations.

Here’s why free shipping matters—and how to offer it without eating into your bottom line.

What is ecommerce free shipping?

Ecommerce free shipping is when online retailers send purchased goods to customers free of charge.

By removing shipping costs on certain items, online retailers motivate online shoppers to purchase those products. Free shipping is often a competitive advantage to online businesses.

Free shipping isn’t usually included with every purchase from every retailer. Many ecommerce stores offer free shipping to encourage more customers to purchase online.

Shoppers often need to qualify for free shipping. Depending on the retailer, free shipping might be obtained in one of the following ways:

Customers may need to reach a minimum order value to qualify for free shipping. For example, spending over $35.

As a limited-time free shipping promotion code to new email newsletter subscribers.

Exclusively during peak sales periods.

As one of a customer loyalty program’s perks.

On select products or combinations of products.

Retailers set conditions like these to keep free shipping from negatively impacting their profit margins.

Some online stores may always offer free shipping, no matter how much a customer spends on their purchases. This can enhance the shopping experience and boost brand loyalty.

Free shipping is appealing to customers who prefer simple pricing structures. It also helps reassure customers they won’t run into unexpected charges during checkout.

Brands often use free shipping policies as part of the marketing strategy to encourage customers to shop with them.

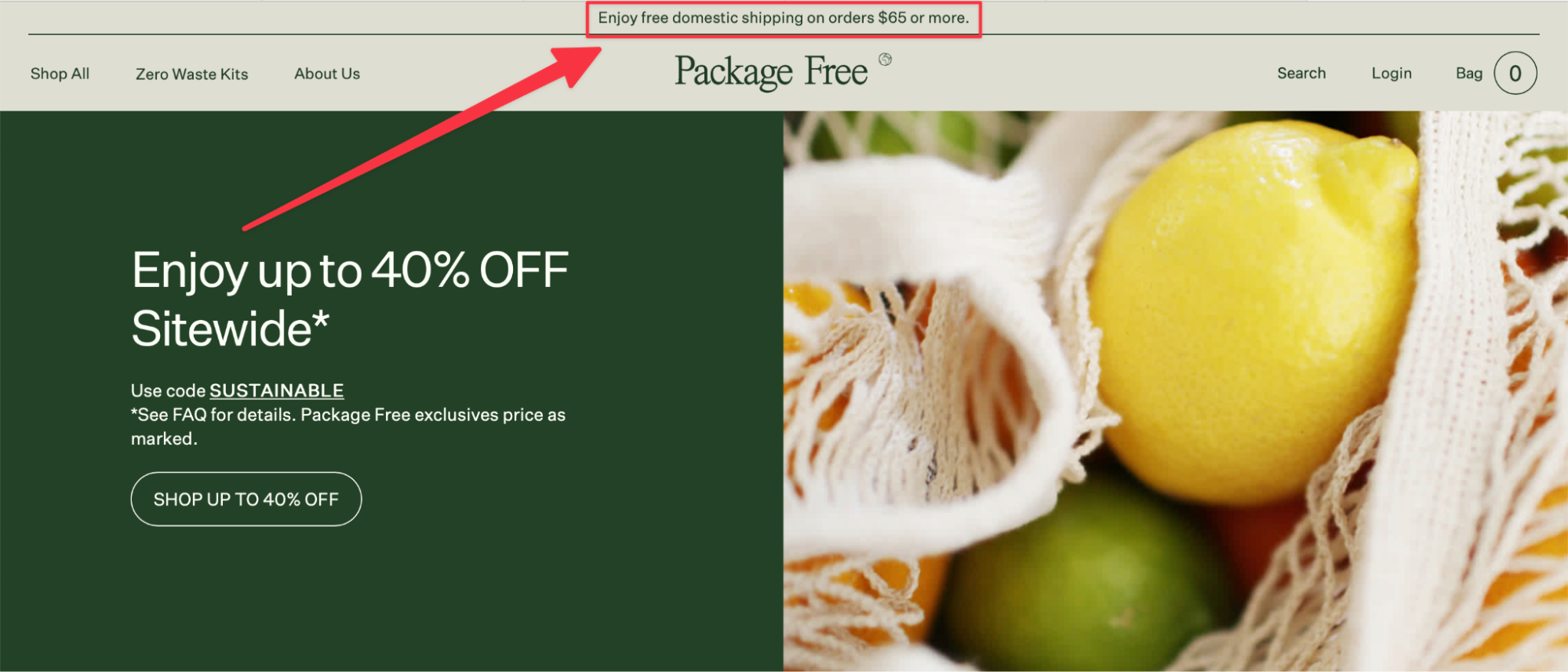

For example, sustainable packaging brand Package Free offers shoppers free domestic shipping on orders of $65 or more. It advertises this on a top banner on its homepage.

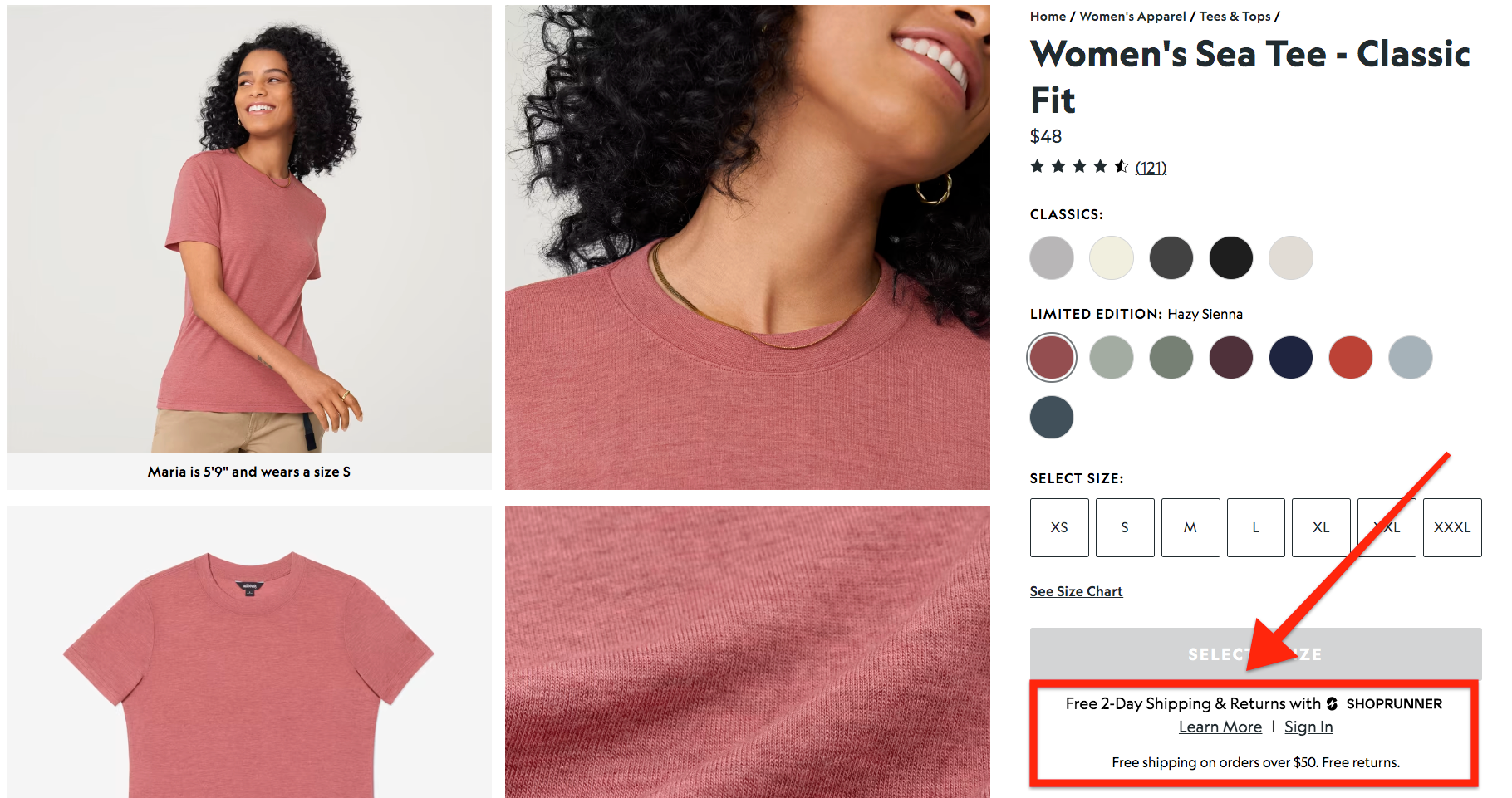

Similarly, clothing brand Allbirds offers free shipping (within the US) for orders above $75. It displays shipping terms and conditions directly below product descriptions.

The threshold you set for free shipping will depend on your brand’s margins and goals, and the cost of shipping to your business.

Steps for offering free shipping

A substantial 75% of consumers prefer free shipping to fast shipping, indicating that cost savings are more valued than speed of delivery. Offering free shipping has gone from a “nice to have” option to an essential.

But nothing is ever free, including shipping. There’s always a cost to pay somewhere along the line.

Ecommerce businesses face the challenge of how to offer customers free shipping and balance their expenses.

Here are three ways to start offering free shipping to customers without losing money.

Increase product price

To offer free shipping on all products, you’ll need to increase the price of your products to cover the cost or pay out of your margins. Doing so will help you keep up with the rise in demand for speedy worldwide shipping.

If increasing your product prices would make your items too expensive for customers, you may need to consider supplying your products from other regions with lower shipping costs.

Gary Grant, the founder and executive chairman of the UK toy store The Entertainer, recently told Time magazine, “I had to stop importing giant teddy bears from China because their retail price would have had to double to add in higher freight costs.”

It’s always important to consider whether your product price point is right for a free shipping strategy. For instance, if you sell low-cost items, raising the product price tag may cause you to lose more customers than you gain by offering free shipping.

Increase LTV

Free shipping is often a hallmark of a great customer experience. When customers love shopping with your brand, they’re more likely to return.

By increasing customer lifetime value, your brand can offset the costs of free shipping. If customers are going to consistently buy from your business, it makes sense to offer free shipping.

Free shipping often helps ecommerce stores stand out from competing brands. Customers may even specifically choose to shop with retailers that offer free shipping. For example, Amazon Prime generates high LTV through its subscriptions that provide free shipping on most items. Many customers even cite free shipping as the main reason why they shop with the retail giant.

Offer bundles

Nearly half of consumers will add extra items to their carts just to qualify for free shipping. Pre-bundling items that are often purchased together (kitting) can help you lift AOV (average order value) and lower your shipping costs. The more items you can ship together, the lower your cost ratio is to ship one item.

The CEO of A Good Company, Anders Ankarlid, says that free shipping is only sustainable for buying multiple products at once.

“We don’t believe it’s OK that you buy one notebook and expect free shipping—that’s not sustainable for anyone,” he says. “So we incentivize our customers to buy a little bit more at the same time. That way they get better bulk pricing and we can ship the order in the most sustainable way possible.”

Recommending product bundles to customers can help them more easily find the items they’re looking for too. Instead of hunting all over your site for similar items, they can instead buy items together as a kit.

It’s also a fulfillment technique that can work well for both businesses that fulfill orders and for those who outsource the job.

Building kits in bulk, based on customer purchase histories and trends, can help businesses that fulfill orders themselves save time. Merchants who outsource fulfillment can save time and money, as a bundle will count as only one SKU rather than two.

Free shipping minimum threshold calculation

Your free shipping minimum threshold is the lowest price you’re prepared to send purchased items to customers for free. Your free shipping minimum threshold depends on shipping costs, average order volume, and customer preferences.

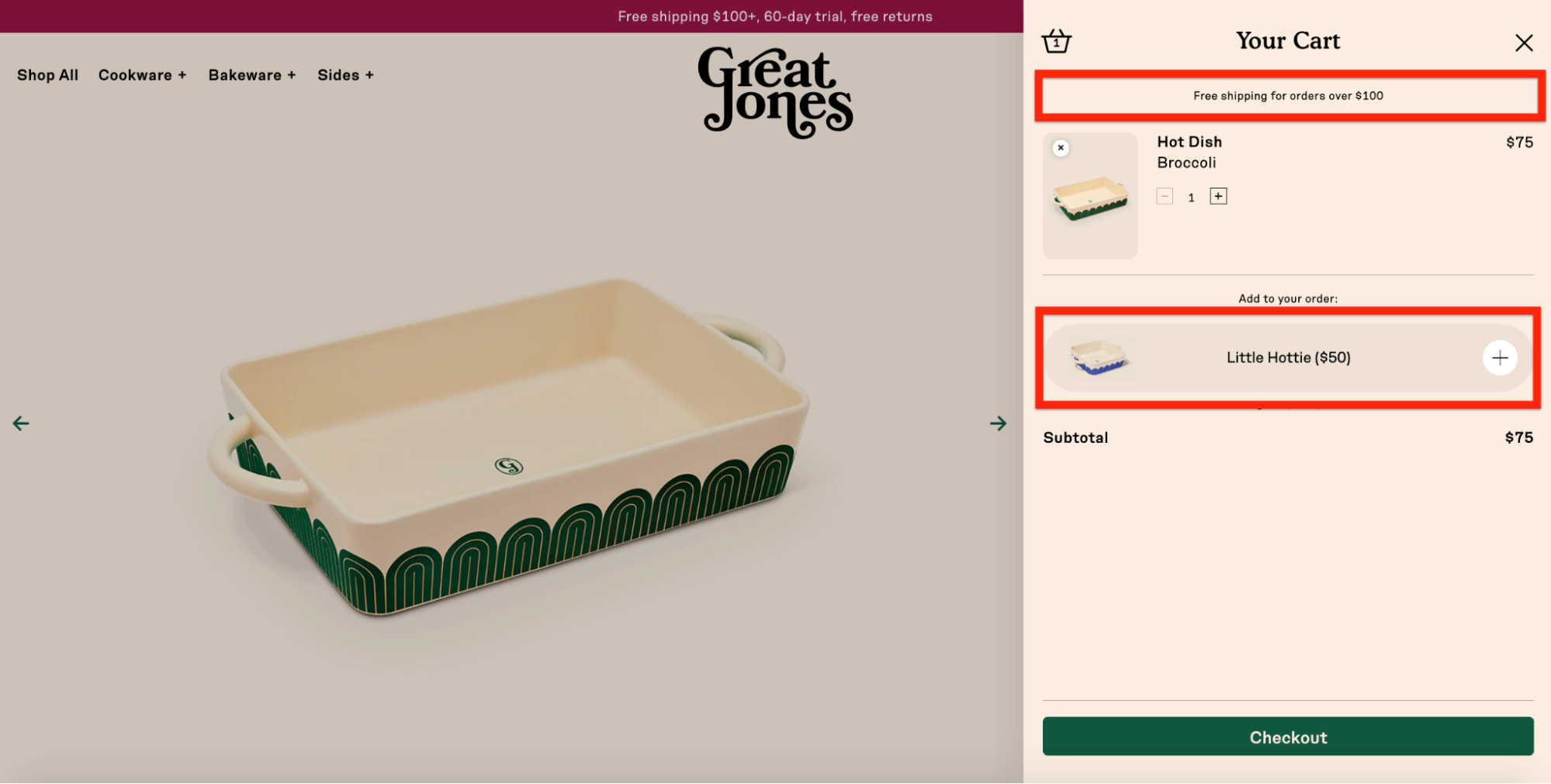

This is how DTC cookware brand Great Jones increases conversions and average order value. It offers free shipping at $100, pushing customers to order more than one item.

Then when they add the item to your cart, Great Jones incentivizes the move to free shipping with an in-cart upsell. In this case, a large oven-proof dish is $75, while the upsell item (a mini oven-proof dish) is $50.

How to calculate your free shipping minimum threshold

If you choose to offer free shipping, it’s important to calculate a minimum threshold number that’s right for you.

One important metric is your average order value (AOV). For example, let’s say you have some orders already for the following amounts: $75, $100, $150, $200, $300, and $350. If you add them all up and divide by the total number of transactions, (five in this case), you’ll get your AOV of $165.

You could also use the median order value (MOV) to calculate a free-shipping threshold. The median is the midpoint in a set of values that has an equal number above and below it. So the median order value means that half of all your orders are above the median value and half are below it.

Using the numbers from the example above, we get a MOV of $150, which is right in the middle. The MOV has a benefit over the AOV in some scenarios when the AOV may be off due to outliers like extremely high- or low-priced SKUs, which can skew the average and distort the value of your median cart.

Ideally, free shipping is set just high enough above your median order value or average order value that it nudges customers to add one or two extra items they were previously denying themselves.

What to consider when calculating free shipping minimum threshold

To work out your free shipping minimum threshold, always keep in mind the following factors:

AOV: Remember there may be outliers, such as extremely high- or low-price SKUs that can distort the value of your median cart.

Average shipping costs: These may be impacted by average box size, geography, and the weight of the products you’re sending out. Determine both what you’re charging customers, as well as what’s being charged to you by carriers.

Transaction fees: Other charges you’re paying, like custom duties or credit card fees.

Cost of products, packaging, and your profit margin: How much of a hit are you willing to take to your overall profit?

Once you’ve got some numbers to work with, you can run a standard A/B test on your site to determine the sweet spot at which you can boost both conversions and profit. Then, it’s time to embed your threshold throughout the customer shopping experience, such as by adding this free progress shipping toolbar, which makes the bonus tangible for consumers as they shop.

Free shipping minimum threshold best practices

Experiment with different thresholds above your median order value or average order value to find the threshold that performs best. There’s never a silver bullet for conversions: When you mix in variables such as price, images, and product innovation, these factors will all ultimately influence customer behavior differently. Routine testing may prove that you can steadily increase your threshold once higher thresholds are accepted as the norm.

Embed the threshold throughout the customer experience—including not-so-subtle reminders during the checkout to coax more shoppers to add items to their carts and earn the free shipping you’re offering.

To sum up, your own free shipping minimum threshold should:

Give consumers rational “permission” to add more items

Act as a positive incentive to “earn” something of value

Lean on the potentially negative experience of paying for something they’re used to getting for free

3 Benefits of offering free shipping

Offering free shipping offers your brand three key benefits:

Reduces cart abandonment

Entices customers to make a purchase

Customers like many shipping options

Reduces cart abandonment

According to a 2023 Baymard research study, the main reason (47%) for customers abandoning shopping carts in the US was “extra costs too high,” including shipping, tax, and other fees.

And since the cart abandonment rate in the US currently sits around 86% for mobile and 77% for desktop users, it’s vital to identify ways to encourage customers to follow through with their purchases.

By offering free shipping, you make it easier for customers to hit Purchase. They won’t feel surprised by additional charges and are less likely to back out at the last moment.

Sophia Rinkert Williams, the owner of Shopify store Luna's Link, agrees that offering free shipping results in fewer obstacles for customers.

“Psychologically, free shipping leads to a smoother, more seamless checkout experience. There are fewer pauses as shoppers work their way through the steps, which brings the sale to a close faster,” she says. “As a shopper myself, there have been times where I’ve abandoned a cart because the checkout process was too time-consuming or too expensive. The faster and cheaper we can make it, the better!”

Entices customers to make a purchase

Free shipping is also often a better incentive than discount codes for encouraging online shopping and account creation. Sofia Voudouroglou, a content marketing executive at sustainable t-shirt store creator Teemill, explains how providing occasional free shipping weekends causes a spike in sales.

“We do regular freepost weekends where shipping is free Friday to Sunday,” she says. “We sponsor freepost weekends so store owners get the same profit per item. We find that one freepost weekend per month, around payday, has the most impact on sales compared to other offers like buy-one-get-one-free, discounts, etc.”

Promoting short-term free shipping also has the benefit of boosting sales. Voudouroglou adds, “Teemill brands saw three times more sales than usual over our most recent freepost weekend at the beginning of June! On average, stores see at least 20% more traffic and 24% more sales during those promotional weekends.”

Customers like many shipping options

People like choice, so if you offer free shipping, don’t stop there, but provide other options. For instance, these other shipping options could include paying a premium for speedy delivery.

Providing customers with multiple shipping options lets them choose the one that suits their preferences. For example, you could offer free standard shipping by default. Packages could arrive within five to 10 business days, but if a customer would like to receive their items sooner, they can pay a shipping fee of between $10 and $40.

Give customers the option to choose sustainable shipping options

Providing environmentally friendly shipping options is a great way to build sustainability into your retail brand. Empowering your customers to choose these options at checkout helps them feel like they’re part of your sustainability efforts by choosing the environmentally conscious shipping option.

Autumn Blakeman, the senior ecommerce account executive at Cake Agency, a Shopify Plus Partner, says that brands can help customers make more sustainable shipping decisions by providing several options.

“Some sites are giving consumers the option to make more sustainable choices when shopping—for example, shipping products via lorry rather than plane,” she says.

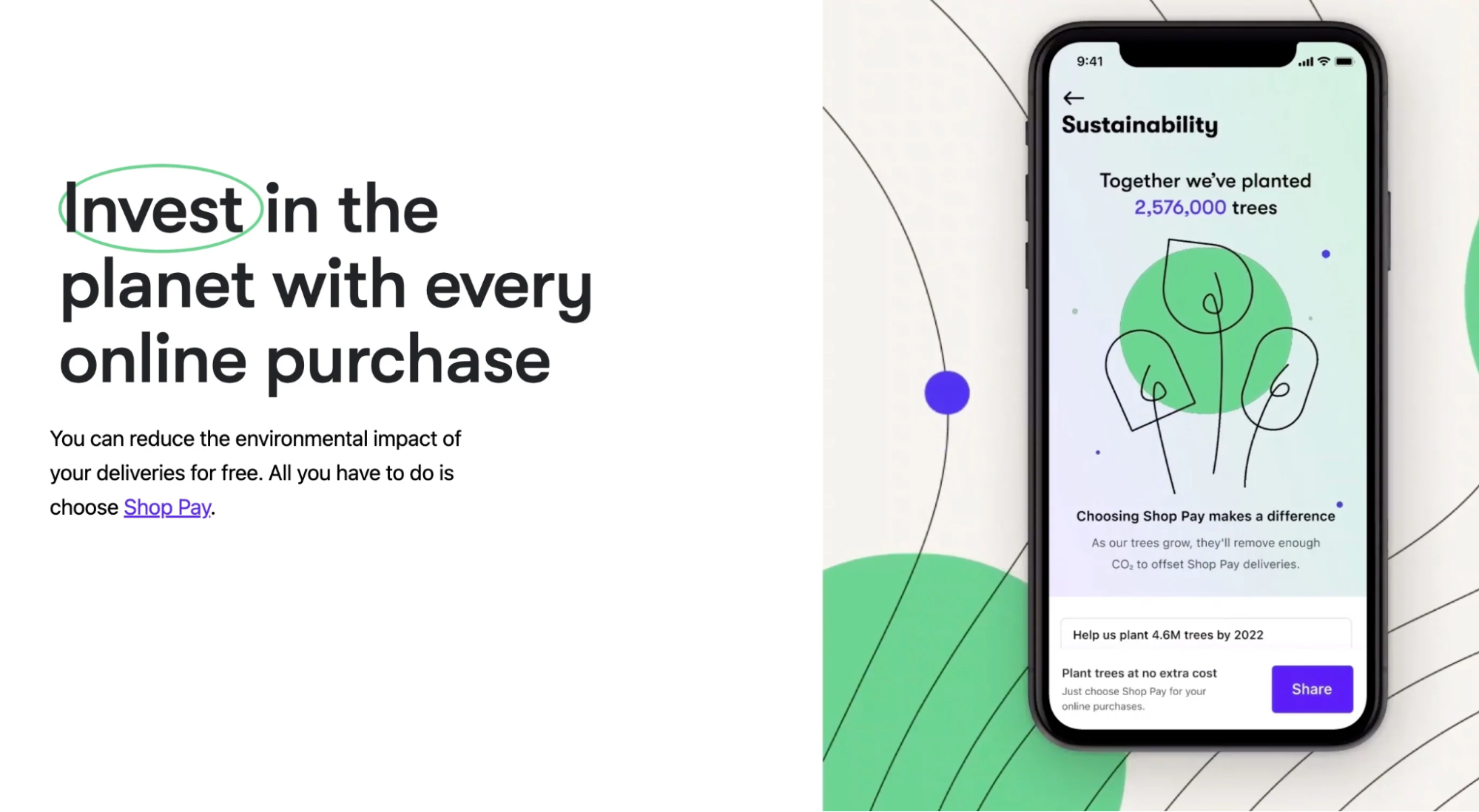

In addition to giving customers different shipping options, you can help them offset their carbon emissions during checkout. For example, Shop Pay will help communities plant trees with every checkout, which helps offset the environmental impact of shipping.

Using Shopify Plus to offer customers free shipping

With Shopify Plus, you can set up free, flat, or calculated shipping charges that show up in the checkout for your customers.

Global and nationwide retailers can set up shipping zones that group countries or regions together for specific shipping rates. For example, in a shipping zone in the US, you could set a flat rate of $5 and another flat rate of $2.50 for orders that are over $50.

Alternatively, you may want to use shipping profiles to set up different shipping rates for certain products and locations. For example, if customers buy a five-kilogram tub of protein powder, your flat shipping rate is $4, but if they buy three or more tubs, you offer free shipping.

You can add free shipping rates to any shipping zone or profile so customers don’t pay anything for shipping at checkout. Or you can offer free shipping when certain criteria are met. These criteria can be based on a minimum order amount or orders over a certain weight.

Using Shopify Plus, you can set free shipping to be your default rate on all orders. This method makes managing your shipping rates easier and still lets you add additional paid shipping rates for certain products or orders over certain values or weights.

Follow these steps to set free shipping as your default rate:

From your Shopify admin, go to Settings > Shipping and delivery.

Next to General shipping rates, click Manage.

For each shipping zone, add the free shipping rate:

Click Add rate.

Enter the name for the rate.

Make sure that the value of the Price field is 0.

Click Done, and then click Save.

How Bathorium cuts shipping costs by 70%

Shopify Plus Merchant Success Manager Greg MacDonald founded and runs his own store, Bathorium. Because Bathorium is based in Canada, working with a 3PL that could efficiently reach its US-based customers was critical to its success.

Shipping from Canada was very expensive and variable for Bathorium, costing about 50% of its AOV and often difficult to predict. Before working with a 3PL, Bathorium would spend $18 to $25 on a one-pound shipment, and it would take a minimum of seven to 10 business days to reach the destination.

When Bathorium developed a strong US presence by partnering with ShipBob for fulfillment, it achieved a reduction of 70% on shipping expenses in the US. This also led to a higher conversion rate, allowing it to grow from a 20% US customer base to 40% in under a year.

“Speeding up deliveries and keeping them affordable for customers is a top concern for us,” Greg says. “With ShipBob, we can comfortably assign a shipping cost to each order by pinpointing the product weight and destination ZIP code. It makes it a lot easier to spend marketing dollars when we know exactly what shipping costs are going to be.”

Start offering free and flat rate shipping today

Having a free shipping offer is a powerful marketing tool because it reassures customers they won’t be charged a surprise high shipping fee when they place their orders. Also, consumers expect free shipping these days, or at least the option to have it.

Whether free shipping is free or it’s simply a perception created in the mind of customers who meet certain thresholds, it can help boost your ecommerce store’s conversions.

By offering free shipping in your online store, you may lower your store’s cart abandonment rate, increase average order value, and encourage more shoppers to join your loyalty program.

How to offer free shipping and two-day delivery FAQ

What is free shipping?

Free shipping is a popular option for online shopping where customers don’t need to pay an additional shipping charge during the checkout process.

Is free shipping really free?

Free shipping is not really free. Retailers either need to lower their profit margins, increase the product price, or provide free shipping through a promotion or a loyalty program. How long does free shipping take?

Most standard rate free shipping takes three to five business days. However, this depends on many factors, like the freight company, potential delays, and the retailer’s agreement with the handler.

Is free shipping faster?

Most free shipping is standard rate delivery time. Some shoppers pay a premium for faster shipping.

Read more

- How to Block the Ad Blockers & Whether You Should

- How Ecommerce Teams Get Buy-in To Sell More

- Shopify Flow Templates you can use During COVID-19

- Ecommerce Customer Experience: Mastering Acquisition and Retention

- Overhauling Your Customer Acquisition Model: How to Spend Your Budget Where It Really Counts

- The Master Guide to Google Channel

- How To Create a Memorable and Shareable Unboxing Experience for Your Brand

- How to Personalize for Unknown Black Friday Cyber Monday Mobile Visitors

- Omnichannel Inventory Management: Solving Optimization Challenges to Increase Profits